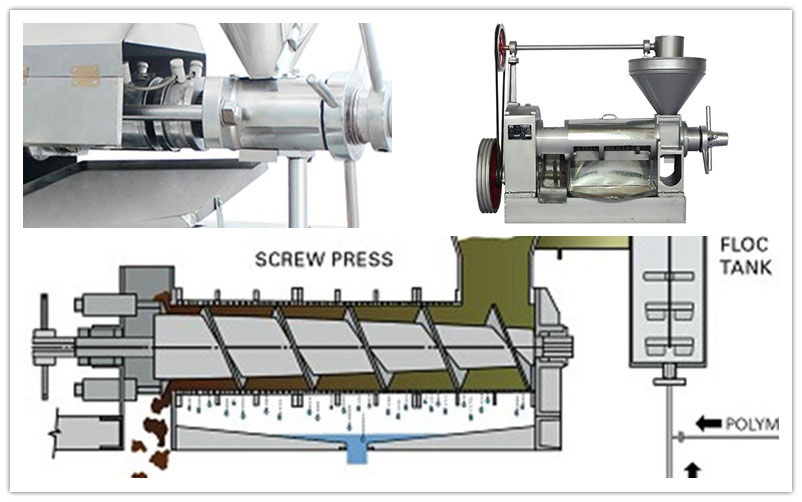

The Role of Pressing Screw in the Expeller

Pressing screw is the key working part of screw oil press. Usually, 5-7 sections of screws are set up on the screw shaft, which is in the pressing cage. For different models the number of sections is different. The screw shaft of the model 68 is one section. The pressing cage and the screw shaft form the spiral channel-pressing chamber. By the power of motors, the pressing screw rotates along with the shaft, pushing the materials between the thread continuously toward the cake outlet.

The root diameter of the screw shaft is gradually thickening and the screw pitch is gradually decreasing so that the space in the chamber becomes smaller and smaller, and the pressure is increasing gradually, the size of the materials is compressed and the oil is pressed out. In this process, the thread also continuously turns the materials outward, the materials near its surface rotate with the shaft, so the micromaterials are moving in different directions with different speed, and there is relative motion between the particles. Under the high pressure, with the moving of the materials, there forms great frictional resistance between the materials and pressing screw as well as the chamber. The friction generates the heat, which combining the pressure meets the requirement of oil pressing, destroy the cells of the material and improve the oil yield.

Notes about the Using of Pressing Screws

1. Besides the great extrusion force and friction force, the pressing screw also suffers large torque-the force that makes it rotate, produced by the motor-so it is prone to abrasion. The abrasion decreases the pressure in the pressing chamber, and further reducing the output, so the pressing screw must be changed in time. At most after one year, you should have the screw changed. If used improperly, the time will shorten to half a year. The new pressing screw should go through a running-in period to make it smooth since rough screw will also influence the output.

2. The adjoining screws should be tightly assembled by tightening the locknut, otherwise, the cake dregs may squeeze in so that the disassembly will be difficult and there may be oil leakage at the locknut. The disassembly should be taken when the screws are hot.

3. Before using the new screw oil press, use the abrasive cloth to polish the outside surface and internal surface of the pressing screw.

Why is the Screw Shaft Stuck?

If used improperly, the machine may stop running suddenly and the screw shaft will be stuck. The possible reasons are listed below:

1. Large feed intake for the new machine without running-in. New machines should go through 4-8 hours running-in period to increase the temperature of the chamber. Feed hot oilseeds or dry cake with hot water slowly into the hopper and press repeatedly. Too fast feeding will cause blocking and the pressure in the chamber will increase suddenly, making the pressing cage break.

2. Long time no feeding will make discharging difficult and cause blocking. To avoid this problem, feeding should be continuously and evenly, the cake should not be too thin. The thinner the cake, the larger is the pressure.

3. The materials are not cleaned beforehand, stones, metals or other hard foreign materials enter into the pressing chamber.

Once the screw shaft is stuck, turn the power off at once, stop feeding and eliminate the blocking, then start pressing again.