Introduction of DTDC Desolventizer Toaster Dryer Cooler

DTDC (Desolventizer Toaster Dryer Cooler) integrates the functions of wet meal desolventizing, drying, and cooling, having the features of simple operation and stable product quality. The meal after desolventizing can be packaged directly. The Desolventizer toaster is the key equipment in the desolventizing system of the cooking oil solvent extraction plant. Wet meal discharged from an oil extractor usually contains 25-35% solvent. The Desolventizing toaster can remove the solvent in the wet meal for recycling and obtain the qualified finished meal. DTDC desolventizer toaster is used for processing direct extraction meals of soybean, cottonseed, rapeseed, camellia seed, etc. The meal after processing is used for animal feed ingredient applications.

Technical Data of DTDC Desolventizer Toaster Dryer Cooler

| Model | Capacity | Heat transfer area | Height | Power | Weight |

| DT140 | 30 t/d | 10 m2 | 6020 mm | 15 kW | 5 t |

| DT160 | 30-50 t/d | 11 m2 | 6020 mm | 18.5 kW | 6.5 t |

| DT180 | 50 t/d | 11.5 m2 | 6300 mm | 18.5 kW | 8 t |

| DT200 | 80 t/d | 13.2 m2 | 6300 mm | 22 kW | 12 t |

| DT220 | 100 t/d | 15.5 m2 | 6300 mm | 22 kW | 14 t |

Characteristics of Wet Meal Desolventizing Process

- Unique steam permeable tray design, the secondary steam produced from the desolventizing layer can have sufficient heat exchange with the pre-desolventized meal. Good desolventizing effect, saving steam consumption and reducing the load of the condensing system.

- The desolventizing layer adopts automatic feed valve, ensuring constant material level in the desolventizing layer and enough desolventizing time.

- The reducer has reliable performance and long service life.

- The wet fines catcher on the top of the desolventizing toaster adopts atomization nozzle to fully catches the fines in the discharged mixed vapor, which is good for the heat transfer effect of the first evaporator and avoids the fines entering into the water separator

Advantages of Wet Meal Desolventizing Toaster

- Wet meal desolventizing toaster can inactivate and destroy the anti-nutrients like urease and trypsin in the meal to improve its quality.

- Wet meal desolventizing toaster can control the degree of protein denaturation in the meal and effectively improve its nitrogen solubility index.

- Desolventizer Toaster can better regulate the color and flavor of the meal.

- DTDC desolventizer toaster can better reduce the residual solvent in the meal and regulate its moisture and temperature, so as to ensure the minimum solvent consumption and safe use of the meal.

- DTDC desolventizer toaster has large driving torque, large load weight.

Desolventizing Process of Solvent Extraction Plant

Wet meal scraper conveyor→seal auger→DTDC→finished meal scraper conveyor→meal storehouse

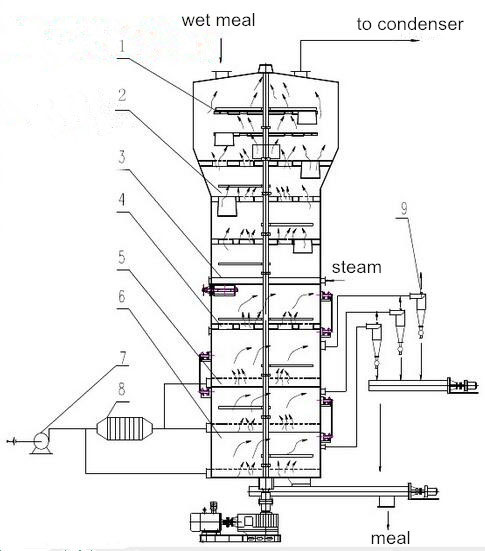

DTDC desolventizer toaster dryer cooler consists of the pre-desolventizing layer, desolventizing layer, drying layer and cooling layer.

- Through scraper conveyor and seal auger, the wet meal discharged from the oil extractor is sent to the pre-desolventizing layer of the desolventizer toaster, where the meal is heated by indirect steam. Part of the solvent evaporates and the temperature of the meal rises.

- The pre-desolventized meal falls into the steam permeable tray. The tray has holes on the bottom so that the secondary steam produced from the desloventizing layer can penetrate the materials layer on the tray to predesolventize the solvent in the meal, meanwhile indirect steam also enters through the jacket on the bottom to heat the materials layer.

- The meal falls into the desolventizing layer. Direct steam enters into the desolventizing layer through the holes on the bottom. Distilled by direct steam, the solvent in the meal is removed completely. The wet fines catcher catches the fines in the discharged mixed vapor, and the vapor then enters the first evaporator.

- After desolventizing, the water content of the meal is high. The desolventized meal falls into the drying layer to remove the water.

- After cooling to a proper temperature in the cooling layer, the meal is sent to the meal storehouse for packaging through scraper conveyor.