Crude Edible Oil Deodorization Overview

Edible oil deodorizing towers in the deodorization process are coordinated with bleaching and degumming processes to achieve refining in an oil refinery factory.

The crude oils obtained from different processes have different levels of odor. Some smell of oil is loved by people, such as the fragrance of sesame oil and peanut oil, whereas others are disliked by people, like rapeseed oil & rice bran oil’s offensive odor, and the offensive odor even affects the oil quality which should be removed. Some of these odors are natural, and some are generated in the production of oil and the process of oil storage. Odor components in natural oils are 0.1~1% and the odorous material is related to the amount of free fatty acids(FFA): the odor will be eliminated if the FFA in oil is reduced to 0.01~0.03%.

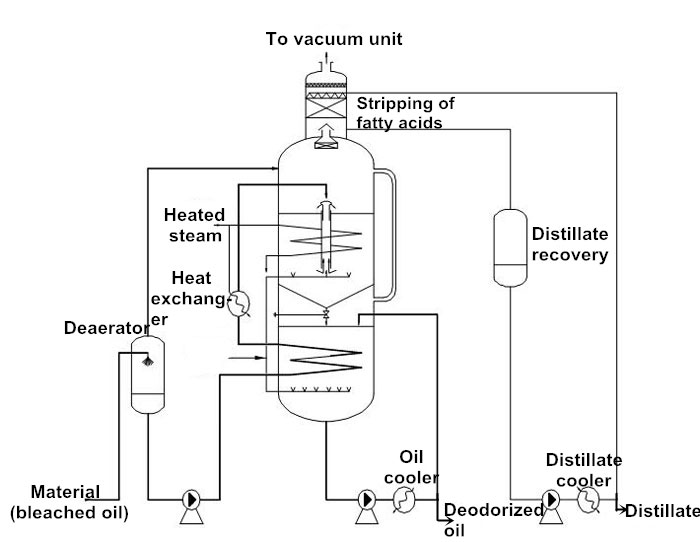

The Edible Oil Deodorization Process utilizes the difference in odor and triglyceride volatility (vapor pressure) to remove oil’s offensive odor by steam distillation under high temperature and vacuum. The edible oil deodorization process can not only remove the oil’s offensive odor, enhance the oil’s smoke point, and improve the flavor of the edible oil, but also improve the oil’s stability, chroma, and quality. Because it also removes FFA, peroxides, some heat-sensitive pigments, the rotten oil protein volatile decomposition products, and pesticide residues. Thus, Edible oil deodorization is highly valued in the production of high-grade oil products and oil deodorization is the final process of edible oil refinery processing.

Edible Oil Deodorization Steam Distillation Working Principle

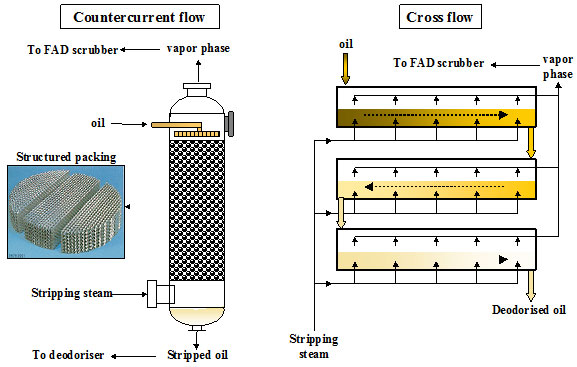

Steam distillation, also known as water vapor distillation or stripping, is a key step of oil deodorization. Its principle is small molecules and odor components in oil evaporate more easily than triglycerides at high temperatures & under negative pressure. When inputting steam to pass through the odorous oil, the steam-liquid surface is in contact, and volatile odor components in oil escape to the steam at the ratio of its partial pressure, then the steam is saturated with odors and is discharged from the exhaust outlet, to achieve the purpose of removing odor components.

Edible Oil Deodorizing Equipment

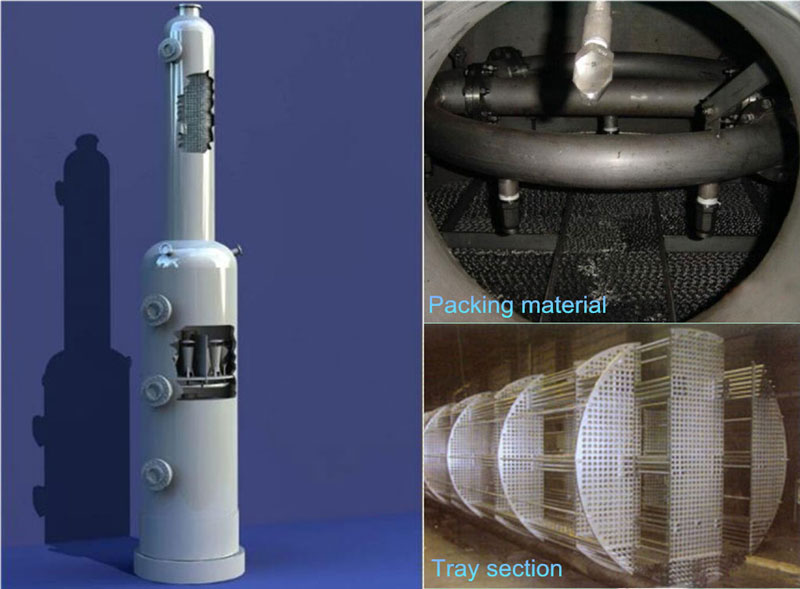

Deodorizing equipment such as intermittent deodorization pots and continuous deodorization towers mainly adopt the principle of steam distillation to deodorize oil, but the intermittent deodorization machine has the shortcomings of long operation time, high steam consumption, and low heat utilization, which is about to be eliminated. Thus, a continuous edible oil deodorizing tower is the commonly used deodorizer machine in edible oil refinery factories. Several types of continuous deodorization towers are usually used in edible oil refining lines, such as tray deodorization towers, packing deodorization towers, and combined deodorization towers. We will design the plant according to your condition.

Continuous Deodorization Tower Introduction

The continuous deodorizing tower is the best choice for large-scale edible oil refinery factories with the advantages of compact structure, high steam utilization, and easy maintenance. The type of continuous deodorizer tower has developed from plate deodorization tower (single shell) to tray deodorization tower (multiple-layer shell), while in recent years the packing deodorization tower and combined deodorization tower have also been introduced into production.

The tray deodorization tower is equipped with a vertical cylindrical shell and a series of trays to ensure all processes (heat recovery, final heating, cooling, deodorization) are carried out in specific layers of trays, respectively. But with the growing demand for lowering the residence time at high temperatures, a new process of tray deodorization tower combined with packing deodorizer method is developed, and it is particularly suitable for refinery factories with frequent oil variety replacement to process oil which has a complex source, poor quality, and deep color, such as rice bran oil, tea seed oil.