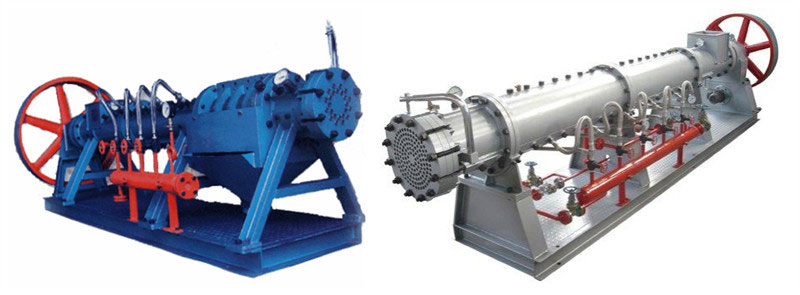

Oilseed Puffing Machine Introduction

An oilseed puffing machine is for preprocessing high oil-content materials like rapeseeds, corn germ, or various pre-pressed oil cakes before sending them into an oil solvent extraction workshop. The puffing machine is suitable for soybean, rape seeds, cotton seeds, rice bran, etc. The puffing process of oil materials can improve oil yield, reduce energy consumption, and save investment in edible oil plants.

Features of Oil Materials Expansion Machine

1. Improve oil yield and production efficiency can be increased by 30-50%

2. Shorten the extraction time and raise the leaching rate.

3. Improve the quality of edible oil

4. Reduce energy consumption

5. Decrease the residual oil in oil meal

6. The oilseed puffing machine adopts a new type of hydraulic conical plug to discharge oil material, which is convenient for opening and closing, and user-friendly.

Working Principle of Oilseed Puffing Machine

Oil materials are fed into the inlet of the puffing machine through the magnetic chute by the spiral quantitative feeder. The steam is added to the extruder cylinder through the direct steam throttle valve. The main spiral shaft, consisting of broken tooth screws, rotates in the cylinder to mix, press, heat, shear, and rub oil material. Cells of oil material are completely destroyed, and the oil in cells is fully exposed. Then the oil material is extruded from the mold hole on the template at high temperature and high pressure. When they are extruded out, the pressure suddenly decreases as well as the moisture evaporates rapidly, which causes the puffing of oil material.

Technical Data of Oil Material Puffing Machine

| Model | Capacity(T/D) | Power(kw) | Dimension (L*W*H)(mm) | Net weight(kg) |

| ALYJPZ-16 | 60-80 | 37/55 | 3400*1216*1238 | 1695 |

| ALYJPZ-20 | 80-200 | 75/90 | 4085*1216*1238 | 2150 |

| ALYJPZ-25 | 200-400 | 90/110 | 4850*1267*1633 | 3170 |

| ALYJPZ-30 | 400-600 | 132/160 | 6210*1267*1633 | 4098 |

| AlYJPZ-35 | 600-900 | 220/250 | 6115*1600*1942 | 6147 |

Functions of Oilseed Bulking Machine

1. Improve the productivity of the oil solvent extractor

Due to the bulk density of extruded oil materials being increased by 20-30%, oil solvent extractors and stemming machines can process more oil material.

2. Increase the oil leaching rate and shorten oil leaching time.

After extrusion, cells of oil material are destroyed completely, and the porosity is increased, so the permeability of solvent and mixed oil through oil material is improved. Therefore shortens the oil leaching time efficiently and improves oil leaching productivity.

3. Puffed materials absorb less solvent, so it is easy to dissolve.

After puffing, oil material has better permeability and drainability, the absorption of solvent is decreased by about 20%, and a load of desolvation and solvent recovery is reduced, thus saving steam consumption.

4. Increase the concentration of mixed oil, so decrease the load of evaporation of mixed oil.

The puffing process destroys the cells of oil material and improves its permeability, which decreases the solvent ratio from 0.8:1 to 0.6:1 compared with materials without puffing, and the concentration of mixed oil is increased from 20% to 28-30%. Therefore, reduces the load of the mixed oil evaporation system and solvent recovery, saving steam consumption of the mixed oil evaporation section.

5. Enzymes in oil materials are passivated after puffing, so the quality of leached oil is improved.

In the puffing process, enzymes and anti-nutritional factors are passivated, which avoids the effects of lipoxygenase and phospholipase on the phospholipids in oilseeds, and reduces the content of non-hydrated phospholipids in leached crude oil, increases the total phospholipid content in the leached crude oil. This improves oil refinery efficiency, oil quality, the yield of phospholipid by-products, and the quality of the phospholipid product in the hydration degumming process.

| Phosphorus content of crude oil(mg/Kg) | Phosphorus content of degumming oil(mg/Kg) | Phosphatidyl acetone insoluble substance% | Phospholipid composition(%) | |||

| Lecithin | Brain phospholipid | Inositol phospholipid | ||||

| The raw flake leaching process | 840 | 184 | 65.8 | 34.19 | 18.07 | 19.97 |

| Puffed flakes leaching process | 985 | 67 | 74.3 | 39.78 | 12.36 | 19.95 |

6. The processing capacity of the flaking machine is improved.

The requirement of puffed flakes thickness is lower than raw flakes without puffing, and the flaking thickness is relaxed, which improves the processing capacity of the flaking machine.

7. Reduce energy consumption in the oil solvent extraction processing workshop.

Because puffing of oil material can improve the concentration of mixed oil and decrease the solvent absorption of the wet meal, to reduce the consumption of solvent in the oil bleaching process; improvement of production capacity reduces the consumption of tones of oil materials in the oil production process; total production cost is reduced.