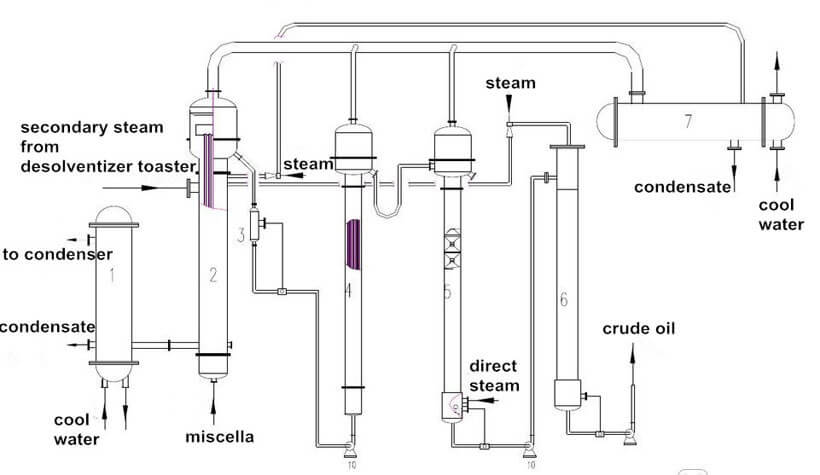

The Vacuum evaporation system is used for removing the solvent from the miscella from the oil extractor to obtain the crude extracted oil. The main equipment includes the first rising film evaporator, the second rising film evaporator, and the disk stripping column.

Utilizing the difference in boiling point between the oil and solvent, the evaporator heats the miscella so that most of the solvent vaporizes and separates with the oil. Then utilizing the difference of volatility between the oil and solvent, the stripping tower adopts a steam distillation method to remove the residual solvent in the miscella.

After evaporation and steam stripping, crude extracted oil of low residual solvent content is obtained. The solvent vapor enters the condenser to be recycled to use. The solvent evaporation system adopts negative pressure evaporation technology, using the secondary steam from the desolventizer toaster as the heat source of the first evaporator and using the steam jet pump to vacuumize the system to make it works under negative pressure, having low evaporating temperature and good oil quality, saving steam and solvent consumption.

Operational Process of The Solvent Evaporation System

miscella pretreatment→miscella tank→the first evaporator→the second evaporator→stripping tower→crude extracted oil

- The thick miscella from the oil extractor is pumped into the hydrocyclone to remove the fines by centrifugal force.

- The miscella is pumped into the miscella tank which has a settling separation function.

- Then the miscella is pumped into the tube pass of the first rising film evaporator. The shell pass adopts the secondary steam from the desolventizing toaster and the exhaust steam from the steam jet pump as the heat source to evaporate the solvent in the misella. The solvent vapor and miscella enter the vapor & miscella separator.

- The miscella is pumped into the heat exchanger to be heated by the high-temperature crude oil from the stripping tower.

- The miscella is pumped into the second rising film evaporator. The shell pass uses indirect steam as the heat source to evaporate the solvent.The solvent vapor and miscella enter the vapor & miscella separator. The first evaporator and the second evaporator work under the same negative pressure.

- The miscella from the second evaporator is pumped into the disk stripping column from the top and fills up the overflow tray of the first group of the disk. The miscella flowing out forms a thin film on the cone-shaped disk and flows down. The annular tray holds the miscella which then flows to the overflow tray of the next group of the disk. With the flowing down of the miscella, the direct steam rises up from the bottom and countercurrent contact with the miscella to remove the residual solvent.

- The crude oil is pumped out from the bottom of the stripping tower and then pumped into the heat exchanger for heat transfer with the miscella from the first evaporator. After being cooled by a crude oil cooler, the oil is pumped into the crude oil tank and later pumped into the refining workshop.

Formation of Negative Pressure in Vacuum Evaporation System

The solvent vapor from the first evaporator and the second evaporator enter the evaporating condenser. The condensate is pumped into the economizer, while the non-condensing vapor is pumped out by the steam jet pump and pumped into the shell pass of the first evaporator. The steam jet pump results in the negative pressure of the condenser which leads to the negative pressure of the evaporator.

The solvent vapor from the stripping column enters the stripping condenser. The condensate enters the water separator, while the non-condensing vapor is pumped out by the steam jet pump and pumped into the shell pass of the first evaporator, resulting in the negative pressure of the stripping condenser and stripping tower.

The non-condensing vapor in the shell pass of the first evaporator enters the economizer and is condensed by the condensate from the evaporating condenser. The condensate enters the water separator, while the non-condensing vapor enters the desolventizing condenser.

Advantages of Negative Pressure Evaporation Technology

- Saving energy

1)Adopting negative pressure evaporation technology, the evaporating temperature of the first rising film evaporator is lowered, making it possible to use the secondary steam from the desolventizer toaster as the heat source to heat the miscella, saving heat and cooling water. The replenishment of exhaust steam from the steam jet pump saves fresh steam for the first evaporator. The vacuum evaporation system adopts high-temperature crude oil from the stripping column to heat the miscella from the first evaporator, increasing the inlet temperature of the second evaporator, thus saving energy. The use of economizer also helps save energy. The steam consumption and circulating water consumption of the whole production line has been reduced.

2) The oil from the vacuum evaporation system has good quality and is easy for degumming, meanwhile the dosage of bleaching clay is also reduced.

3) Running under negative pressure, the solvent consumption of the workshop has also decreased.

- Having lower operating temperature than normal pressure evaporation technology, the crude oil obtained has low peroxide value, light color and low residual solvent content below 0.02%, the quality of crude extracted oil has been improved, reducing refining loss.

- The use of secondary steam from the desolventizer toaster can reduce the load of the condensing system, so that the configuration area of the condenser can be reduced, saving investment.

- The whole system runs in the micro negative pressure environment, reducing the leakage of the solvent vapor.The safety performance of the extraction workshop has been improved.

- Adopt automatic control system, the key parameters of the solvent evaporation system is automatically controlled, reducing the labor intensity, enhancing the operation stability.

- The service life of the equipment has been prolonged since normal pressure evaporation technology has oil of inferior quality which can cause scaling.

- The disk of the stripping column is of stainless steel construction, effectively reducing the coking of oil film.The column trays are connected by flanges, easy to maintain and clean. The steam and miscella contact evenly and thoroughly,no steam short-cut, good stripping effect, low steam consumption.