Palm Kernel Oil Production Line Overview

A palm kernel oil production line is a series of interconnected processes that extract oil from palm kernel seeds. We offer complete palm kernel oil production lines and palm fruit oil production lines to meet your large volumes of palm oil production needs. Our patented palm oil processing technology transforms palm kernels into high-quality stable palm kernel oil through an efficient, meticulous, seamless, and sustainable process. Whether you are expanding your current palm oil mill plant or setting up a new palm oil plant, our complete, state-of-the-art solutions cover every stage of palm oil production to maximize quality, efficiency, and yield.

Why Choose Our Palm Kernel Oil Production Lines?

Top Supplier: More than 100,000 sqm factory area, over 580 employees, 8 Large-scale workshops, 120 sets of equipment, and over 30 years of experience in oil machine processing.

Large Palm Oil Mill Project Contractor: We can undertake a full set of palm oil production lines, including palm fruit oil and palm kernel oil production lines.

Expert Engineering: Our team has extensive experience in designing and implementing industrial-scale palm oil production solutions.

High Quality: Every palm oil machine is built with top-grade materials to ensure longevity and consistent performance.

Global Service: Hundreds of successful overseas projects. We support clients worldwide, providing consulting, installation, and after-sales service for continued operational success.

Customer Support: We’re committed to supporting you beyond installation. Our after-sales team is available to provide: Ongoing Technical Support. Maintenance Services. Training for Operational Efficiency. Spare Parts Supply

Contact Us Today

Tell us your palm kernel oil mill plant project needs, and we’ll help you set up a production line that meets your goals for quality, efficiency, and profitability.

Advantages of Our Complete Palm Kernel Oil Production Line

- High Efficiency: Processes large volumes of palm kernels quickly and consistently.

- High Oil Yield: Optimized processes maximize palm kernel oil extraction and quality.

- Versatility: Can handle multiple processes, including pressing, solvent extraction, refining, and fractionation.

- Quality Control: Advanced refining methods ensure the palm kernel oil meets industry and regulatory standards.

- Sustainability: Waste products like palm kernel cake are repurposed and often used as animal feed or in bioenergy.

- Versatile Applications: Supports both edible oil production and non-food uses like soap, cosmetics, and biodiesel.

- Energy-Efficient Design: Our machines and processes are designed to save energy and reduce operational costs.

Customize Palm Kernel Oil Production Line

We offer customization options to suit your specific palm kernel oil production needs. Whether you need a modular design for easier scale-up or require specific refining processes, our engineering team will work closely with you to design a tailored solution.

Contact us for a free quote now!

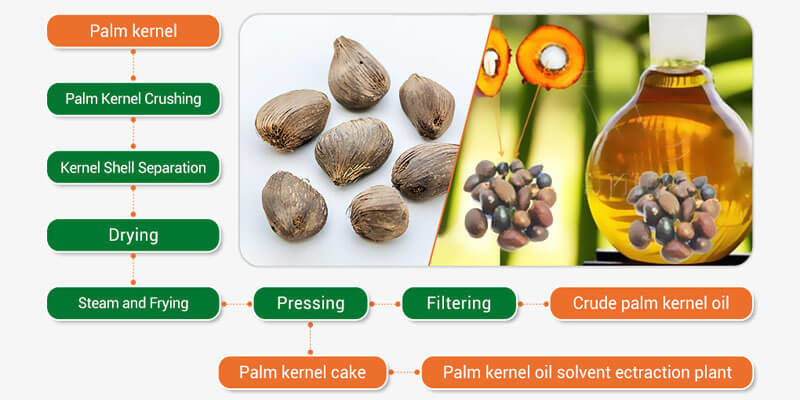

Palm Kernel Oil Mill Plant Working Process

The palm kernel seeds contain around 35% to 45% of oil in them which is quite considerable. The palm kernel oil is mainly derived and recovered from the innermost kernel of the oil palm fruit by pressing technology. Our palm kernel oil production line consists of several interconnected stages, each with specialized machinery to streamline and enhance your palm kernel Oil production. The basic steps in palm kernel oil extraction are Palm Kernel Cleaning, Crushing and Shelling, Palm Kernel Oil Pressing, Palm Kernel Solvent Extraction, Filtration and Clarification, and Palm Kernel Oil Refining.

Palm Kernel Pre-treatment Process

Palm Kernel Cleaning: The palm kernels are first cleaned to remove impurities such as dust, fiber, and stones. Clean seeds help prevent machine damage and ensure a smoother oil extraction process.

Palm Kernel Crushing: Palm kernels are quite hard, so they are crushed to increase the surface area for oil extraction, which facilitates more efficient oil extraction.

Palm Kernel Drying: This process removes excess moisture from the kernels. Too much moisture can negatively impact oil yield and quality, so drying is critical before further processing.

Palm Kernel Cracking and Shelling

Palm Kernel Cracking: Since palm kernels are encased in a hard shell, the cracking process breaks the shells, allowing the seeds to be separated for oil extraction.

Shell and Kernel Separation: Specialized high-efficiency palm kernel shelling machines separate the kernels from the shells to ensure only kernels are processed.

Palm Kernel Oil Pressing

Mechanical Pressing: After pre-treatment, kernels are fed into palm kernel screw press machines that apply high pressure to extract crude palm kernel oil (CPKO). Mechanical pressing can typically extract up to 45-50% of the oil content. Equipped with the automatic temperature-controlling device and crude oil filter tank, Our integrated screw oil press operates easily and has high oil output. After pressing, the crude palm kernel oil is filtered through the filter cloth and stored in tanks temporarily. The specially designed feeder ensures the feeding is continuous and average, thus the pressing process is smooth and efficient.

Heating: Some systems employ heat to improve oil extraction efficiency, making the process smoother and increasing the yield. Heating also helps reduce the oil’s viscosity, easing its flow.

Continuous Pressing: In large Palm Kernel Oil production lines, continuous pressing is used to increase the amount of oil extracted. This step may also include a secondary press to further extract oil from the residual cake.

Palm Kernel Solvent Extraction Process

In Large Palm Kernel Oil Mill Plant

Solvent Extraction: Solvent (often hexane) is used to dissolve and separate the oil remaining in the press cake. This method increases yield, especially for high-capacity plants.

Desolventizing: After extraction, desolventizing removes any remaining solvent from the extracted oil and meal. Desolventizers reclaim the solvent for reuse, making the process efficient and cost-effective.

Meal Recovery: The remaining solid (de-oiled meal) is often utilized as animal feed, adding value to the palm kernel oil production line.

Crude Palm Kernel Oil (CPKO) Filtration and Clarification

Filtration: After extraction, crude palm kernel oil may contain impurities, including residues and fine particles. Filtration removes these, resulting in clearer oil.

Degumming: This step removes phospholipids, a type of impurity that can affect oil quality. Degumming also prepares the oil for refining by improving its stability.

Settling Tanks: Use settling tanks to allow heavy impurities to settle at the bottom, which can then be removed to further purify the oil.

Palm Kernel Oil Refining Process

Refining is essential to make the oil suitable for edible or cosmetic applications. It also increases shelf life and enhances quality by removing free fatty acids, phospholipids, and other undesirable components. There are two main refining methods:

Physical Refining: Physical refining uses distillation to remove free fatty acids. It’s often more energy-efficient and retains the oil’s natural properties.

Chemical Refining: Chemical refining neutralizes free fatty acids using a chemical agent. It’s preferred when high FFA levels are present.

The typical steps in refining include:

Fractionation (Optional)

Purpose: Fractionation separates palm kernel oil into liquid (olein) and solid (stearin) fractions. Olein is typically used in food, while stearin is used in non-food products, like soaps and cosmetics.

Dry Fractionation: This process crystallizes the oil without chemicals, followed by filtration to separate solid and liquid components. The dry fractionation method is cost-effective and ideal for high-purity olein.

Solvent Fractionation: Uses a solvent to improve the separation of olein and stearin, producing a high-quality product with higher purity.

Final Filtration and Storage

Final Filtration: The oil is filtered one final time to remove any remaining impurities before it’s stored or packaged. This ensures a clean, pure end product.

Storage: Refined oil is stored in stainless steel or food-grade containers to maintain quality and protect it from oxidation and contamination. Controlled storage conditions, such as low oxygen exposure and stable temperatures, are maintained to prevent spoilage.