Canola Rapeseed Oil Production Line Overview

We can provide and customize a complete set of 5-5000TPD Canola Rapeseed oil production lines. Our Canola Oil Production Line is a comprehensive processing setup designed to extract and refine oil from canola seeds, resulting in high-quality oil suitable for various applications. The oil content of Canola & Rapeseed is about 40%, so the mechanical oil press and solvent extraction are combined to maximize the oil yield. From Canola seed preparation to pressing, solvent extraction, and refining, each step is meticulously planned to maximize oil yield, maintain quality, and ensure efficient production.

Canola Rapeseed Oil Production Lines Capacities

Small Batch Canola Oil Production Line: Suitable for small-scale operations (under 20 TPD) with basic equipment for seed cleaning, conditioning, mechanical pressing, and simple refining.

Continuous Canola Oil Production Line: Ideal for larger Canola Oil Mill Plants (20–1000 TPD), designed for automated, continuous oil extraction and refining. Mechanical pre-pressing and solvent extraction are applied.

Fully Automated Canola Oil Production Line: Large-scale Canola Oil Mill Plants (1000+ TPD) with full automation, including advanced monitoring systems for precise control, improved efficiency, and higher oil yields.

CONTACT US FOR A FREE QUOTE

Canola Seed Cleaning

Objective: To remove impurities and prepare canola seeds for further processing.

Cleaning Process: Canola seeds are cleaned to remove dust, dirt, plant debris, and stones using cleaning equipment like vibrating sieves, destoners, and magnetic separators. This step ensures the canola seeds’ purity and prolongs the equipment’s lifespan.

Equipment Used: Vibrating Sieve, Destoner, Magnetic Separator, Dryer.

Canola Seed Softening and Conditioning

Objective: The softening process is to adjust the temperature and moisture of rapeseed with steam.

Softening: Canola and Rapeseed seeds are heated in a rotary roaster or flat-bottom roaster to achieve the desired temperature and humidity.

Equipment Used: Rotary or flat-bottom roasters.

Rapeseed Canola Seed Flaking

The purpose of flaking is to flake the broken rapeseeds and canola into thin flakes (from 0.3 to 0.35mm), flaking breaks down the cell walls, enhancing the extraction process, which benefits oil pressing and oil extraction, it also makes canola oil flow out smoothly when pressing or solvent extraction. The flake thickness can be adjusted through a roll pressure adjustment device.

Equipment Used: Flaking Machines

Rapeseed Canola Flakes Cooking

Objective: The Cooking process is to wet, heat, steam, and cook flakes to change their internal structure, which makes it much easier to improve oil yield and facilitate oil extraction.

Cooking process: In the cooker, flakes are exposed to steam and hot air, which adjusts moisture levels and increases the oil’s fluidity. This process maximizes oil yield and quality, laying the foundation for a high-efficiency canola oil production line.

Equipment Used: The Vertical Cooker is the main equipment used in the cooking process, designed for continuous operation and ideal for medium to large-scale production lines.

Vertical Cooker Design: A multi-layer vertical cooker maintains the flakes at a consistent temperature and moisture level as they move through each layer progressively, reaching the ideal conditions for pressing. Features automatic material charging and control, enhancing operational efficiency.

Rapeseed Canola Oil Extraction

Canola oil can be extracted through mechanical pressing or solvent extraction. The method chosen depends on the Canola oil mill plant’s capacity, efficiency requirements, and desired oil yield. Mechanical pressing alone may extract 70–85% of the oil, which is suitable for the small Canola and Rapeseed oil mill plant with a capacity of under 20 tpd. In the large Canola and Rapeseed oil production lines, the solvent extraction process is designed following the mechanical pressing to extract the rest oil.

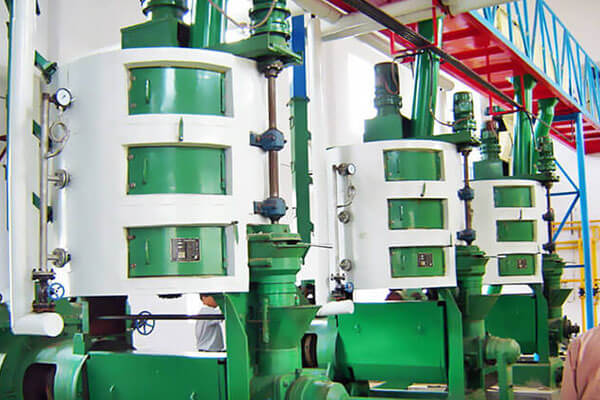

Mechanical Rapeseed/Canola Oil Pressing

Objective: To extract a significant portion of the oil using a mechanical press before solvent extraction.

Oil Pressing: The prepared flakes pass through a large screw press that applies high pressure, squeezing out the majority of the oil (typically about 70% of the oil content).

Press Cake Output: After the first pressing, the press cake (which still contains about 20-30% oil) is sent to the solvent extraction section for further processing.

Equipment Used: Large screw oil press. Oil Filter (to remove solid residues from oil).

Canola Rapeseed Oil Cold Press

The cold oil pressing process is the simplest and most traditional method to extract canola and rapeseed oil, which omits the heating and chemical leaching process of the oilseed and preserves the nutrients of rapeseed oil to the greatest extent. The cold pressing keeps the characteristics of pure natural, high-quality oil, generally does not need to add additives, and can be preserved for a long time. However, the oil yield is relatively low compared with the hot pressing process.

Rapeseed Canola Oil Solvent Extraction Plant

The solvent extraction process includes four sections. Solvent systems, desolvent systems, condensing systems, and recovery systems. After the extraction process, we can get wet canola meal and crude canola oil. Wet canola meal can be sold as animal feed. The crude canola oil still contains solid impurities, chemical impurities, and odors, so we have to refine it in the oil refining plant.

Objective: To extract the remaining oil from the press cake to maximize oil yield.

Oil Extraction Process: The press canola cake is sent to the solvent extractor, where it is immersed in a food-grade solvent (typically hexane) to dissolve the remaining oil. The solid-liquid extraction process ensures full contact between the solvent and the canola oil in the cake.

Miscella Separation: The resulting oil-solvent mixture, known as miscella, is separated from the meal and sent to an evaporation system.

Desolventization: The oil-rich miscella is then heated in a desolventizer to evaporate the solvent, which is recovered for reuse. The extracted oil is known as crude oil and is sent for refining.

Equipment: Solvent extractor, desolventizing-toaster (DT), miscella evaporation system, and Solvent Recovery Unit.

Desolventization of Meal

Objective: To remove any residual solvent from the extracted meal, making it safe for use as animal feed.

Toasting and Drying: The meal is toasted and dried in a desolventizer-toaster (DT) to ensure the solvent is fully removed.

Cooling and Bagging: The solvent-free meal is cooled and bagged, ready for storage or sale as animal feed.

Equipment: Desolventizer-toaster (DT), dryer, and cooler.

Rapeseed Canola Oil Refining Plant

The rapeseed /canola crude oil refining plant is designed to refine crude rapeseed/canola oil into refined canola oil. Through degumming, deacidification, decolorization, and deodorization process, remove impurities in the crude canola oil, such as gums, FFA, pigment, bad odors, etc. Aims at improving the canola oil storage stability, flavor, and color, to get standard quality edible oil, making it suitable for cooking and commercial sale.

Degumming

Purpose: Removes phospholipids, gums, and other impurities that can affect oil quality.

Process: The crude oil is treated with water or an acid (e.g., phosphoric acid) and heated. Through stirring, gums and phospholipids to hydrate and separate from the oil.

Equipment: Degumming tank with heating elements and agitation, centrifugal separator for removing the hydrated gums.

Neutralization (Alkali Refining)

Purpose: Removes free fatty acids (FFAs) that cause oil rancidity, resulting in a more stable oil.

Process: An alkali solution (usually caustic soda) is added to the oil and stirred, neutralizing the FFAs to form soapstock, which is then precipitated and discharged from the oil.

Equipment: Neutralizing tank with heating and stirring, centrifugal separator for soapstock removal, and washing system for removing residual alkali.

Bleaching (Decolorization)

Purpose: Reduces pigments and other color-imparting substances to improve oil appearance.

Process: The neutralized oil is heated and mixed with bleaching earth or activated clay, which absorbs color pigments, metals, and other impurities. The final crude oil is pumped into a leaf filter to circulate and filter out the waste clay adsorbed with pigments, making the rapeseed oil bright in color.

Equipment: Bleaching tank with a vacuum system (to prevent oxidation), bleaching earth dosing system, and leaf filter press for clay removal.

Deodorization

Purpose: Removes odor and taste compounds, ensuring the oil is neutral in flavor and aroma.

Process: The bleached oil is heated under a high vacuum, allowing volatile odor compounds to evaporate. To remove these volatiles, steam is injected to raise the temperature of the deodorized oil to 260°C. All the equipment is made of stainless steel.

Equipment: Deodorization column or tower with a vacuum pump and steam distillation setup, as well as a cooling system.

Filtration and Packaging

The refined oil is filtered to remove any remaining particles and packaged for sale. Packaging can be tailored to meet retail or industrial needs.

Objective: To ensure the oil is pure and ready for storage or sale.

Final Filtration: Any remaining particulates are filtered out using oil filters.

Packaging: The finished canola oil is packaged into bottles or drums for distribution. Packaging machinery may also include labeling and capping systems for retail readiness.

Equipment Used: Plate and Frame Filter, Bottling Line, Labeling Machine.