Why The Edible Oil Decolorizing Equipment Is Essential?

The main composition of the edible oil is triglycerides. Pure triglyceride liquid is colorless and they become white when in solid form. But the common oil has different colors due to different amounts and varieties of pigments in oil, the pigments can be divided into three categories: Organic pigments such as chlorophyll, carotenoids, and gossypol; Organic degradants such as proteins, carbohydrates, and phospholipids; Some chromogens. Not all the pigments are bad, but the harmful pigments would damage oil quality and threaten human health, which should be removed.

The oil bleaching process can remove these harmful pigments from crude oil, as well as some trace metals, residual soap, odorous substances, and residual pesticides. The purpose of oil bleaching is not to theoretically remove all pigments but to improve the color of the oil and provide qualified materials for oil deodorization. What’s more, the decolorization section can avoid oil color reversion and improve the oil product’s shelf life.

Therefore, edible oil decolorization equipment is essential in oil refining plants for producing high-quality edible oils. After decolorizing, the bleached oil will look more transparent and brighter.

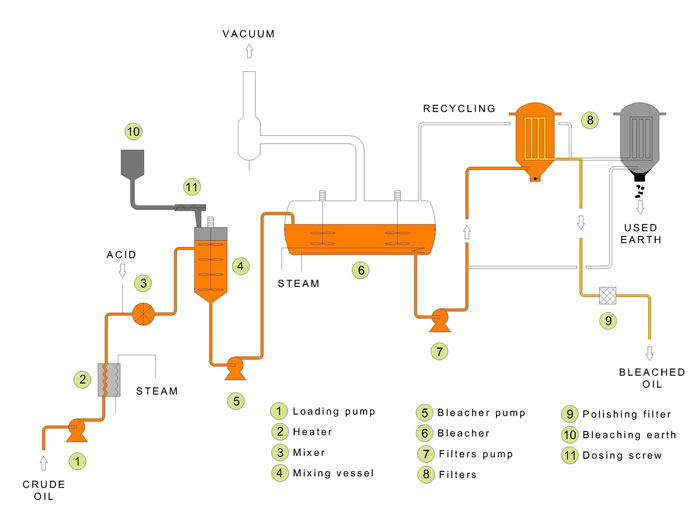

Cooking Oil Decolorizing Equipment Oil Refinery Plant

Oil Bleaching Machine Features

- The oil bleaching machine is made of 304L stainless steel material with mirror polishing treatment. Conform to the GMP standard.

- The machine is equipped with a stainless steel stirring blade, uniform stirring, and convenient cleaning. Please note: the shape and size of the stirring blade can be customized according to customer needs.

- The bleaching machine has an electric control box which a voltage is 220v/380v, a button control and the temperature can be set.

- The machine’s heating pipe is made of 304/316 stainless steel. Acid and alkali-resistant, corrosion-proof, high power, and fast heating.

- Wide application: oil decoloring machine is not only used in the oil refining industry but also can be applied to the fine chemical industry, the cosmetics market, the pharmaceutical industry, etc. With the advantages of reasonable design, great durability, high efficiency, stable operation, low noise, and easy installation, our stainless steel decolorization tank has been widely used in medium and large material processing factories.

Common Methods of Oil Decolorization

In industrial cooking oil production plants, there are many methods for oil decolorization: adsorption decolorization, heating decolorization, oxidation decolorization, chemical reagent decolorization, and so on. Among them, adsorption decolorization is the mostly method in oil refining processes.

Adsorption Decolorization

Oil adsorption decolorization is making use of some substances that have a strong adsorption effect on pigments(such as bleaching earth, activated clay and activated carbon) to adsorb pigments and other impurities in oil under certain conditions. Adsorption decolorization can not only achieve the purposes of improving oil color and removing gum but also effectively remove trace metal ions in oil and some substances that cause the poisoning of hydrogenated catalysts, so as to provide a good condition for further oil refining (hydrogenation, deodorization).

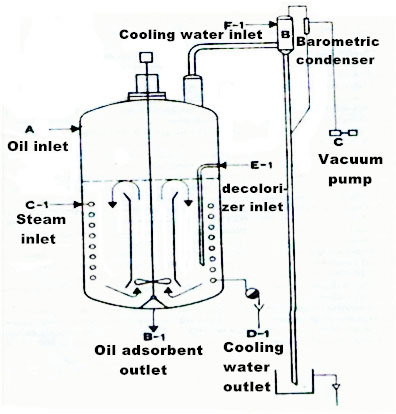

Intermittent type adsorbent decoloring process

In the intermittent type decoloring process of edible oil, oil & adsorbent mixing, heating, reacting, cooling and filtering are batch processed in edible oil bleaching pots. Intermittent type adsorbent decoloring process is suitable for small and medium oil refining factory, and the main processing equipment is bleaching tank. The bleaching tank is a closed cylindrical container with a dish cover and a conical bottom. Edible oil bleaching machine is equipped with stirring device and heating coil, and the power motor is fixed on the top cover of it. In addition, bleaching machine has decolorizer inlet pipe, vacuum pump, inlet-outlet-oil-tube, cooling water pipe and steam pipe.

Continuous type adsorbent decoloring process

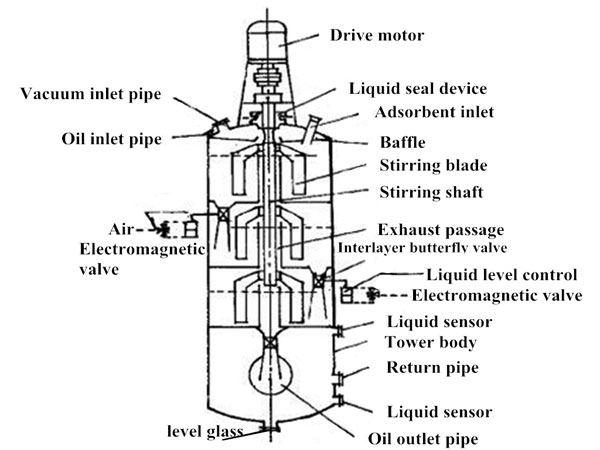

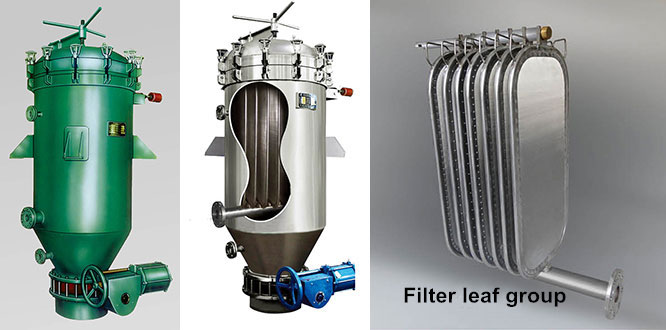

In the continuous type oil decoloring process, the steps of adsorbent’s quantitative supply, oil & adsorbent mixed adsorption, and oil & pigments separation, are in the process of continuous operation. The main processing equipment of continuous type oil decolorization is continuous decolorizer (decolorization tower), leaf filter and vacuum system equipment.

- Decolorization tower is a three-layer oil and adsorbent stirring decolorization device with overflow pipe which can connect with three layers (to control the mixing time of adsorbent and oil). Each of the layers is equipped with a stirring blade, and the second layer of the tower is equipped with an exhaust passage for venting air and the bottom layer is also equipped with a liquid level control device and sensor. In addition, the bleaching tower has a vacuum inlet to prevent oil oxidation and a level glass for machine observation and easy maintenance.

- Leaf filter is mainly composed of the tank body, filter leaf group, pneumatic vibrator, oil inlet tube & oil outlet pipe and slag discharge port.

- Vacuum system equipment can be installed at bleaching machine which effectively prevents the contact between oil and air. The quality of the oil is guaranteed.

Adsorbent

The phenomenon that the automatic change of material in the phase interface is called adsorption. An adsorbent is a solid substance that adsorbs a substance on the surface to reduce its surface energy, and its adsorption capacity is of practical value. There are many adsorbents available for production and application. In oil refining process, the commonly used adsorbents are bleaching earth, activated clay, and activated carbon:

- Bleaching earth

Natural bleaching earth has a certain activity, and its scientific name is bentonite. Its structure is microporous crystals or amorphous and it has a larger specific surface area than other clay. However, its decolorization coefficient is low(which means that when the same batch of oil is decoloring, the ratio of oil column is observed to achieve the same color), and the oil absorption rate is higher, so the bleaching earth is gradually replaced by activated clay.

- Activated clay

Activated clay is a highly active adsorbent which is processed by bentonite as raw material and is widely used in the bleaching of the oil industry. Activated clay has a strong adsorption capacity on chlorophyll and other gelatinous impurities, especially basic group and polar group. After activated clay bleaching, the residual soil smell in the oil can be removed in the deodorization process.

- Activated carbon

Activated carbon is made from carbonized sawdust, bagasse, chaff and hard shell, and then by chemical or physical activation. Activated carbon has loose pores, large specific surface area, high decolorization coefficient, and hydrophobicity. It can adsorb macromolecule substances, especially blue and green pigments. It also can remove trace minerals. In addition, it has a strong adsorption capacity for the gas, polycyclic aromatic hydrocarbons and pesticide residues. But because of activated carbon’s high cost and high oil absorption, it is often used with bleaching earth or activated clay in oil decolorization. The mixing ratio is usually 1: 10~20. Mixed use can obviously improve the decolorization ability, and can remove the smell of drifting soil.

Comparison of different adsorption decolorization methods

| Continuous type | ||||

| Category of comparison | Intermittent type | Tube type | Mechanical mixing | Steam stirring |

| Clay consumption (%) | 3-5 | 1-3 | 3-5 | 1-3 |

| Decolorization temperature (℃) | 90-110 | 100-110 | 90-110 | 105-120 |

| Decolorization time (min) | 30-50 | 20-30 | 30-40 | 20-30 |

| Decolorizing vacuum degree (MPa) | -0.095 | -0.095 | -0.095 | -0.095 |

| Bleaching oil color (Lovibond color) | Y35R6 | Y35R4 | Y35R6 | Y35R4 |

| Equipment cost | High | Low | High | Low |

| Equipment maintenance cost | High | Low | High | Low |

| Steam consumption (%) | 5 | 2-3 | 3 | 2-4 |

| Power consumption | High | None | High | None |