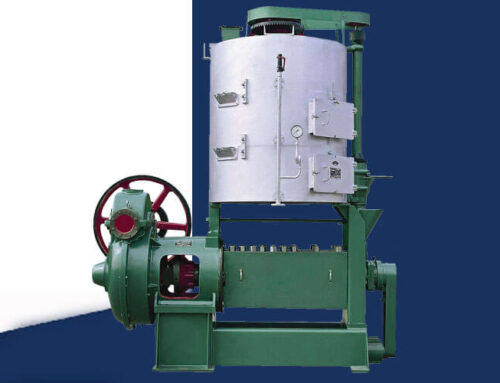

Low-temperature Oil Mill Introduction

Low-temperature oil mill machine adopts low-temperature spiral extrusion method for manufacturing oil. As a new oil making machine, cold screw press has improved the pretreatment process of traditional oil press that the oil materials steaming is no longer required in the pretreatment process. (After cleaning, the oil materials are directly squeezed in the cold press at a lower temperature.) By using the pure natural mechanical pressing technology which does not damage the oil nutrients, the cold press is suited to squeeze oil materials with a high content of oil, such as rapeseed, castor seed, and camellia seed. For camellia seed, 50% of the raw material oil is obtained by the use of cold press machine and then the residual oil in the oil cake can be extracted by re-squeezing or leaching method.

Low-Temperature Oil Screw Press Advantages

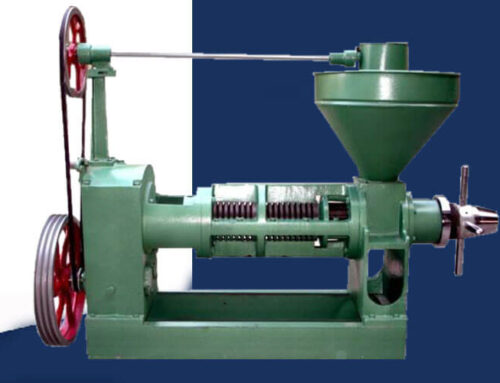

- Cold press oil machine adopts the helical gear transmission system. Energy saving, small load, and low noise.

- The cold press can process a wide variety of oil without steam frying material. The squeeze chamber temperature is low and oil nutrition won’t lose.

- Both for cold press and hot press: the cold press is equipped with automatic bucket-type promotion, and circulation squeezing twice; While hot press generally uses one-time squeezing.

- The machine is made up of steel rod barrel structure to discharge oil. The amount of slag is less and the discharged oil is clear.

- The use of infrared heating technology to ensure that all seasons can be squeezed.

- The machine is equipped with the positive pressure oil filtration system, which is able to quickly remove impurities from crude oil particles. The oil product is clear, transparent and authentic.

Characteristics of YJY-D1 Type Cold Press Machine

-

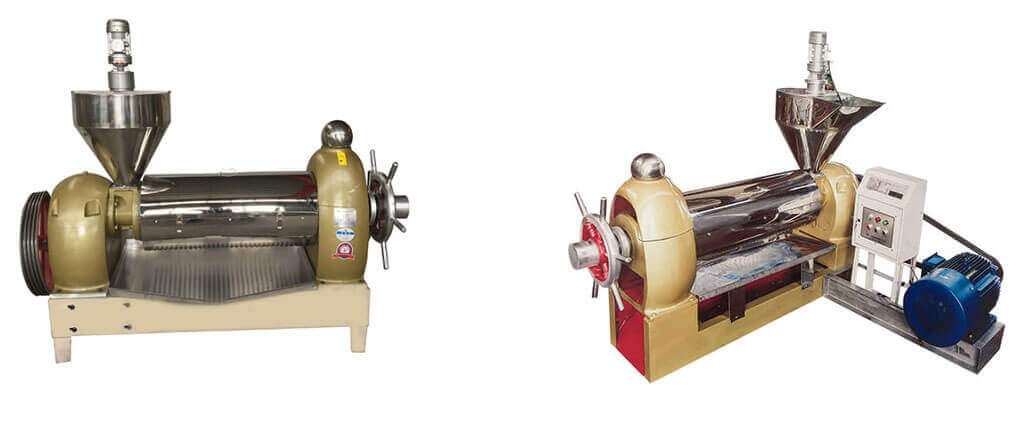

YJY-D1 type cold press could improve oil quality

YJY-D1 type cold press machine could retain the biological activity of various unsaturated fatty acids and other oil-soluble nutrients such as vitamin E, A in oil maximally. Compared with the conventional press machine, the cold press has greatly improved the quality of the oil.

-

Cold press oil machine is environment-friendly and pure-natural

The cold press uses a full physical and mechanical oil making method. After cold pressing, the cooking oil only gained by filtering, drying or other simple refined ways can meet primary food standards, thus avoiding the cold pressed oil being polluted by direct contact with lye, bleaching clay and phosphoric acid in the refining process and oil’s stability being damaged by the high temperature of refining. Cold pressing could maximally preserve the original flavor of the oil and meet the requirements of green, organic and pollution-free food standard.

-

Cold pressed cake contains a high amount of residual oil

In general, the cold pressed cake has 12-20% of the residual oil. If by increasing cold press machine pressure to reduce the residual oil content, along with the cold pressed oil quality would be declined. Therefore, the residual oil in the cake should be extracted by re-squeezing or leaching process, and the secondary oil is obtained. For secondary oil application, it could be processed into refined oil by refining, or as the power source in the factory; the secondary oil could also be used as animal feed without adding extra grease.

Cold Press VS Hot Press

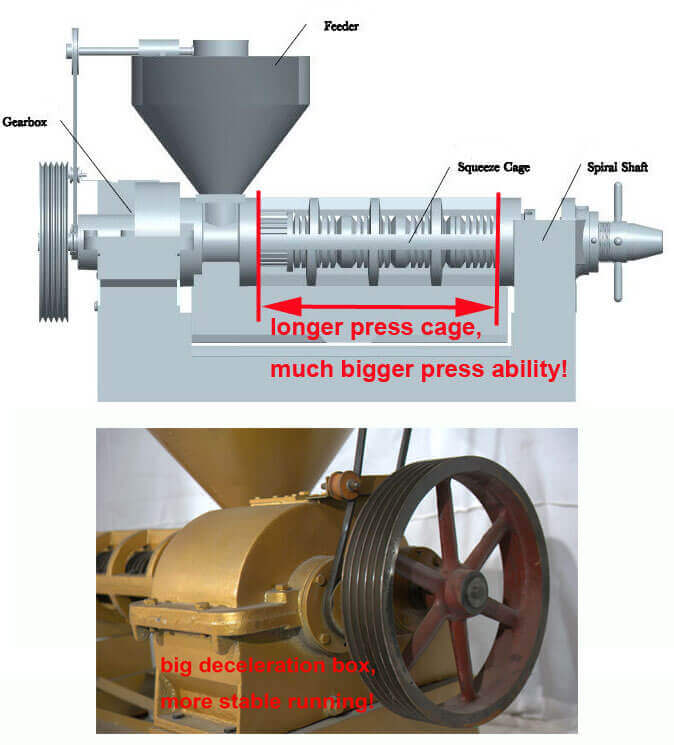

Oil pressing extraction process consists of pretreatment, pressing and refining, and it is divided into hot pressing and cold pressing due to the pressing temperature. The differences of the cold press and hot press are as follows.

-

Hot press

In hot press’s pretreatment process, oilseed would be steamed at high temperature that changes occur in the oilseed inside such as the destruction of oil cells, promotion of protein denaturation, oil viscosity reduction, etc., in order to enhance oil yield. High temperature causes the dark color of crude oil and acid value increasing, so crude oil must be refined before consumption. At the same time, high-temperature oil extraction reduces the amount of bio-active substances in the oil like vitamin E, sterols, carotenoids, etc., resulting in the waste of resources.

-

Cold press

Cold press’s working temperature is generally 60-80℃. Cold-pressed oil retains the natural flavor and color of the oilseed, preserves bioactive substances and has a low degree of protein denaturation.

Please note: Raw materials for cold pressing must be carefully selected, otherwise the quality of cold pressed oil will be affected. In general, cold-pressed oil has a low smoke point and changeable water content, which is not conducive for long-term storage. For eligibility cold press, we recommend YJY-D1 type oil screw press.