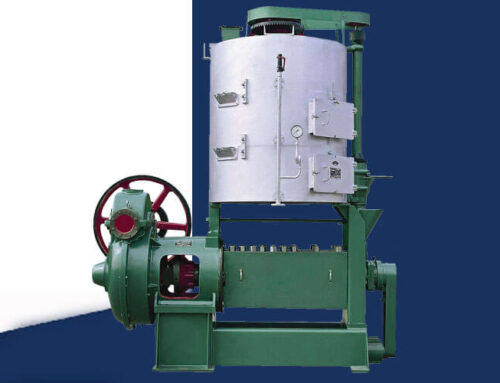

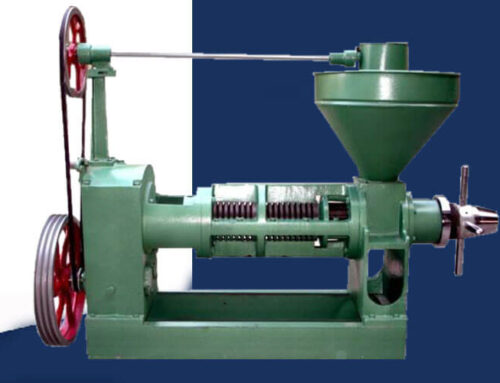

Introduction of Screw Oil Press

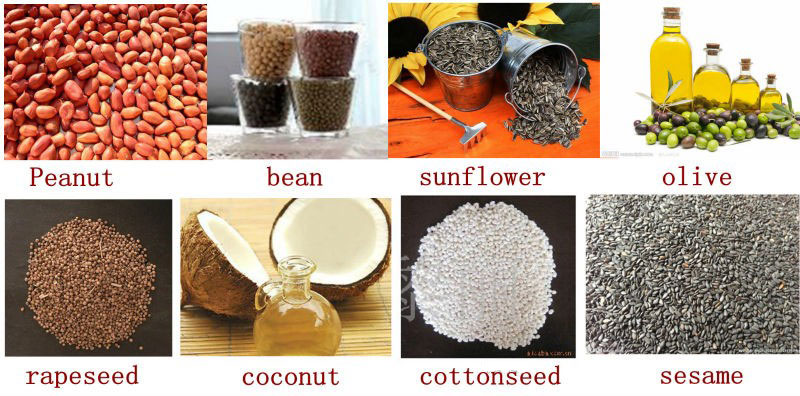

Screw oil press is advanced oil extracting machinery, characterized by its high oil yield with good quality, simple design and convenient operation. The screw oil press machine is for squeezing various oil materials, such as peanuts, rapeseeds, cotton seeds, sunflower seeds and soybeans etc. This type is semiautomatic expeller. Automatic screw oil expeller is supplied too.

Screw Oil Press Features

◆Reasonable and simple design;

◆Small size, covering little space;

◆Saving labor and electricity;

◆Easy operation and convenient maintenance

Screw Oil Expeller Application

Screw oil presses are more suitable for medium-sized and small-sized grain and cooking oil processing factories or specialized households. They can press particle oil materials and powder oil materials, such as rapeseeds, cotton seeds, soybeans peanuts and sesame etc.

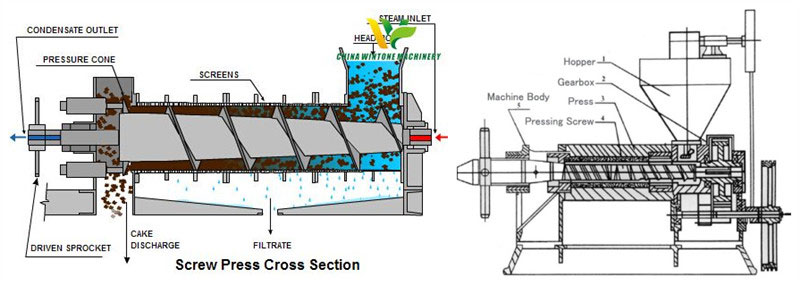

Screw Oil Presser Working Principle

The screw oil press mainly uses the change of pressing screw pitch size and screw thread depth to reduce the volume between screw pitch and pressing chamber, the oil materials get stronger pressure gradually, thus the oil can be squeezed out of the oil materials. Meanwhile, the high pressure in the chamber and the strong friction generates high temperature, which can improve the oil yield.

Notice

▲The temperature of oil manufacture room should keep between 15℃ to 20℃. If the temperature is too low, it will affect the oil yield and oil quality.

▲Before pressing, the oil materials’ moisture content should be appropriate: peanuts with 8%—11%, soybeans with 5%—8%, cotton seeds with 4%—6%, rapeseeds with 6%—8%.

▲After running for three to four months, the screw oil press needs a maintenance. Lubricate the machine parts with machine oil at regular intervals.

Screw Oil Press Technical Data

| Model | Capacity | Power | Dimension | Weight |

| 6YL-68 | 1-1.5 T/D | 5.5 KW | 880*480*660 MM | 140 KG |

| 6YL-80 | 3-4 T/D | 7.5 KW | 1810*560*735 MM | 330 KG |

| 6YL-95 | 3-5 T/D | 7.5 KW | 1910*610*765 MM | 420 KG |

| 6YL-120 | 4-7 T/D | 11 KW | 2060*610*760 MM | 580 KG |

| 6YL-120C | 6-8 T/D | 15 KW | 2100*700*770 MM | 580 KG |

| 6YL-130 | 9-12 T/D | 18.5 KW | 2280*700*770 MM | 760 KG |

| 6YL-160 | 15-20 T/D | 22 KW | 2400*700* 770 MM | 960 KG |