Edible Oil Extractor Introduction

Oil extractor is the main equipment in the edible oil solvent extraction process. The pretreated oilseeds or pre-pressed oil cake are sent to the edible oil extractor by the conveyor, after solvent extraction, miscella and the wet meal are obtained. Crude-extracted oil shall be refined to be edible.

Oil extraction technology can be classified into batch extraction and continuous extraction in terms of operation mode; immersion extraction, percolation extraction, and combined extraction in terms of contact mode; direct extraction, pre-pressing extraction, and expansion extraction in terms of production technology.

Oil extraction technology can be classified into batch extraction and continuous extraction in terms of operation mode; immersion extraction, percolation extraction, and combined extraction in terms of contact mode; direct extraction, pre-pressing extraction, and expansion extraction in terms of production technology.

Types of Edible Oil Extractor Machine

We provide rotocel extractors, loop type extractors, drag chain extractors, and tank extractors to meet your edible oil plant needs.

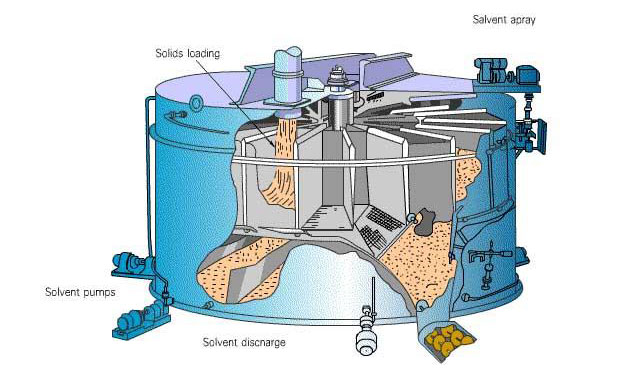

1. Rotocel Extractor

Rotocel extractor is a continuous combined type oil extractor. The rotor consisting of material cells rotates around the main shaft for one cycle to complete the extraction process. Rotocel extractor is the most widely used edible oil extraction equipment, suitable for small and medium oil extraction plant. Rotocel extractor is suitable for the oil extraction of peanut, rapeseed, cottonseed, sunflower seed, sesame, corn germ, camellia seed, flax seed, castor seed, soybean, rice bran, safflower seed, palm fruit cake, palm kernel cake, copra, grape seed, evening primrose seed, etc. The extractor is especially suitable for extraction of various pre-pressed oil cakes. Rotocel extractor is also used for extracting capsicum red pigment.

Advantages of Rotocel extractor

- Simple structure, easy operation, and maintenance.

- Adopt stainless steel stationary grid, with an additional horizontal grid to prevent backflow of thick miscella into the material cells. The grid gap has a self-cleaning effect and is free of clogging.

- Adopt gear-rack drive, unique rotor balancing design, low rotating speed, small power consumption, stable and reliable operation without noise, low failure rate.

- The feed system automatically adjusts the rotating speed of the closed-air aspirator and main engine depending on the incoming amount, so that the materials in the buffer bin can maintain a certain level, which is good for the formation of negative micro-pressure inside the extractor and reducing the leakage of solvent vapor.

- Adopt advanced miscella circulation design, good for reducing the input of fresh solvent, reducing residue oil in meals, increasing miscella concentration, and saving energy through reducing the amount of evaporation.

- High material layer, good immersion effect, good filtration effect, low fines content in the miscella, improving the quality of crude oil and reducing the scaling of evaporation system.

Technical Data of Rotocel Extractor

| Model | Handling Capacity(t/d) | Diameter(mm) |

| JP240 | 10-20 | 2400 |

| JP300 | 20-30 | 3000 |

| JP320 | 30-50 | 3200 |

| JP340 | 50 | 3400 |

| JP370 | 50-80 | 3700 |

| JP420 | 50-80 | 4200 |

| JP450 | 80 | 4500 |

| JP470 | 80-100 | 4700 |

| JP500 | 120-150 | 5000 |

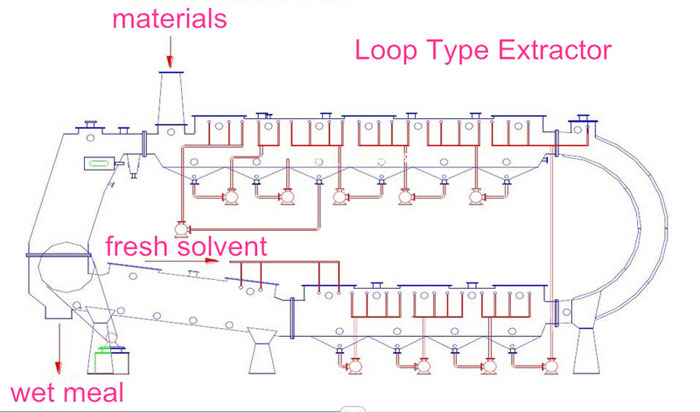

2. Loop Type Extractor

Loop type extractor is a continuous combined type extractor suitable for large-scale oil extraction plant. Dragging by the drag chain conveyor, the materials rotate for one cycle to complete the extraction process. Loop type extractor is suitable for the oil extraction of peanut, rapeseed, cottonseed, sunflower seed, corn germ, camellia seed, flax seed, soybean, rice bran, evening primrose seed, etc.

Features of Loop Type Extractor

- Adopt chain drive, low rotating speed, smooth running without noise, low maintenance cost.

- The materials are turned over twice during the extraction process, the extraction is more uniform and sufficient.

- Shallow material layer promotes fast permeating and draining of solvent and miscella, short extraction time, low solvent content in the wet meal and low residue oil rate.

- The feed system automatically adjusts the rotating speed of the main engine by incoming amount, so that the materials can maintain a certain level in the buffer bin, promoting the formation of negative micro-pressure inside the extractor and reducing the leakage of solvent vapor.

- Adopt advanced miscella circulation design, conductive to reduce the input of fresh solvent, reduce residue oil in meals, increase miscella concentration, and save energy by reducing the amount of evaporation.

- Materials feeding and meal discharging is uniform and continuous, ensuring the stable pressure inside the extractor.

- The machine can be made by sections, convenient for transportation and on-site assembly.

Technical Data of Loop Type Extractor

| Model | Capacity(t/d) | Power(kW) |

| YHJ100 | 80-120 | 4 |

| YHJ150 | 140-160 | 5.5 |

| YHJ200 | 180-220 | 7.5 |

| YHJ300 | 280-320 | 11 |

| YHJ400 | 380-420 | 15 |

| YHJ500 | 480-520 | 15 |

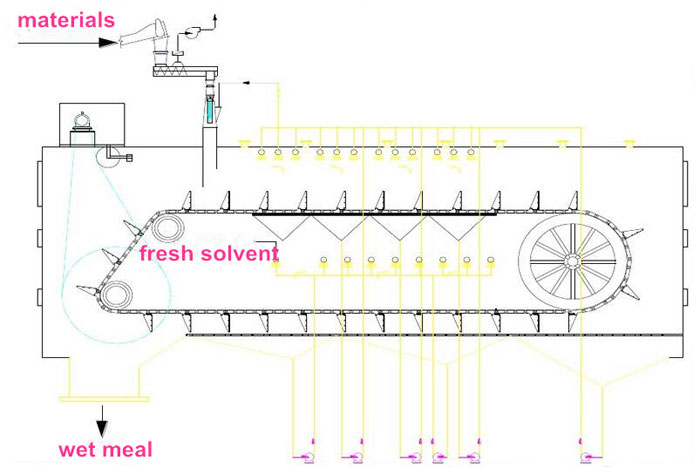

3. Drag Chain Extractor

Drag chain extractor or towline extractor is a continuous immersion type extractor. The drag chain drags the materials to run for one cycle in the extractor to complete the extraction process. Towline extractor is suitable for large-scale oil extraction plant. It is suitable for direct extraction of soybean, rice bran, etc, and pre-pressing extraction of cottonseed, rapeseed, sesame, camellia seed, tung seed, sunflower seed, corn germ, grape seed, etc, as well as alcohol leaching of protein.

Features of Drag Chain Extractor

- Towline extractor has strong adaptability to raw materials. Especially suitable for oilseeds with high oil content and large fines content, having better extraction effect for common oilseeds.

- Advanced technology, simple structure, easy operation, low power consumption, stable and reliable operation, low failure rate.

- The materials are segmented into several independent units on the bed, effectively prevents various grades of miscella from flowing between the material layers, ensuring the concentration gradient between the percolation segments.

- Each material cell forms an immersion area, achieving better immersion effect.

- The materials are fully turned in the towline extractor, good permeability, uniform extraction, low residue oil rate below 0.8%.

Technical Data of Drag Chain Extractor

| Model | Capacity(t/d) | Power(kW) |

| YXJ100 | 80-120 | 2.2 |

| YXJ150 | 140-160 | 2.2 |

| YXJ200 | 180-220 | 3 |

| YXJ300 | 280-320 | 4 |

| YXJ400 | 380-420 | 5.5 |

| YXJ500 | 480-520 | 7.5 |

| YXJ1000 | 1000 | 11 |

4. Batch Tank Extractor

Tank extractor is an immersion type oil extractor. Each extraction tank works in batch with the procedures of materials feeding, immersion, steam blowing, steam stripping, and meal discharging. Several tanks form a continuous extraction process. Tank extractor is suitable for small-scale oil extraction plant with the capacity below 20 TPD. It can be used for extracting oil from rapeseed, sunflower seed, peanut, soybean, rice bran, cottonseed, camellia seed, flax seed, tung seed, grape seed, etc. Tank extractor is also used for extracting oil from spent bleaching clay from the bleaching process.

Features of Tank Extractor

- Simple equipment, low investment.

- Low solvent consumption, low energy consumption.

- Having strong adaptability, especially suitable for specialty and high-value oils.

- Thank extractor has both the function of oil extraction and meal desolventizing.

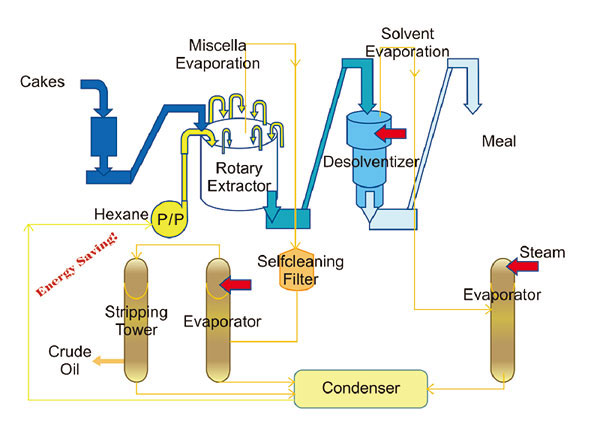

Working Principal of Edible Oil Solvent Extraction

Solvent extraction is an advanced oil manufacturing method widely used in the world. The process includes solvent extraction, miscella separation, wet meal desolventizing and drying, and solvent recovery.

Solvent extraction adopts selected organic solvent that can dissolve oil to extract oil from pretreated oilseeds or pre-pressed cake by immersion or percolation in the oil extractor. The mixed liquor obtained is called miscella. The wet meal is discharged from the meal outlet and sent to the desolventizer toaster to remove the solvent. The thick miscella is filtered and sent to the evaporation system. Utilizing the difference of boiling point between the selected solvent and oil, after miscella evaporation and stripping, the solvent evaporates and separates with oil, thus the crude extracted oil is obtained. The solvent vapor is condensed and cooled for reuse. The crude oil is sent to the refining workshop and undergoes a series of refining processes such as degumming, de-acidification, bleaching, and deodorization to obtain the edible oil.

Advantages of Edible Oil Extraction

1. Residue oil rate of extracting meal can be controlled under 1%, with high oil yield.

2. Good meal quality, favorable for making food or extracting vegetable protein, improving the nutritive value and practical value of feed, and increasing the efficiency of fertilizer.

3. Easy to realize large-scale and automatic production, low labor intensity, low power consumption, and low processing cost.

4. Good work environment: closed production, no leakage, no dust, low production temperature.