Edible Oil Filter Machine Introduction

Plate pressure oil filter machine is used to filter the solid impurity and moisture out of oil, which can improve the oil quality. It can be used alone or with oil processing line.

Edible Oil Filter Machine Features

●Safe and reliable: the pressure, temperature and liquid level has clear data indication and automatic control device

●Low cost and highly efficient: the plate oil filter is one of the advanced filtering equipment with a lower price

●Reasonable structure design: convenient to move and use online

Plate Pressure Oil Filter Working Principle

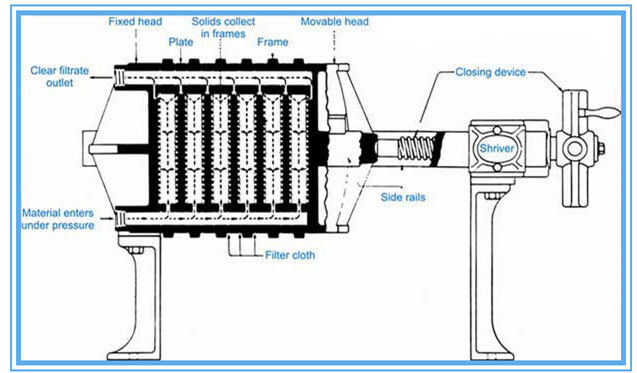

Plate oil filter consists of filter plates, filter frames, oil pump and filter cloth etc. It adopts gear pump to supply oil. There is filter cloth between the filter plate and filter frame as the filter medium. The filter plate and filter frame can form a single filter chamber rely on the pressure of depress device. The filter paper or filter cloth which compressed by the filter plate and filter frame can separate the oil and residue of the crude oil.

Plate Pressure Oil Filter Operation Regulations

1. Press the hole-punched filter papers between each filter plate and filter frame before the operation. Each layer places one or two filter papers according to the filter requirement and filter paper quality.

2. The filter paper should be dried before using with drying temperature around 120℃.

3. When using the used filter paper, the paper should be stoved. The side with residues should face the filter frame to avoid the residues flowing into the filtered oil.

4. If the filter pressure is higher and the filter paper is broke, you can place filter cloth close to the filter plate side to increase the filtration strength.

5. After placing the filter paper, rotate the hand wheel to compress the filter plate

Attention:

▲Keep the machine clean

▲Handle the filter plates and frames with care, for they are fragile

▲Don’t propel the oil filter too fast, or it may be damaged by the fierce impact

▲Compression screw nuts should be added lubricant oil frequently

▲The connecting bolts should be examined regularly to avoid looseness

Plate Pressure Oil Filter Technical Parameters

| Model | Capacity | Power |

| ALC-250 | 100-200 kg/h | 0.75 kW |

| ALC-350 | 200-300 kg/h | 1.1 kW |

| ALC-400 | 300-400 kg/h | 1.1 kW |

| ALC-500 | 300-400 kg/h | 1.5 kW |

Other Types of Oil Filtering Machines

Vertical Leaf Filter: It is the new type oil filtering equipment applied in oil processing industry. It is mainly used for crude oil filtering, and it is also suitable for the filtering and separating of decolorizing adsorbent from oil in the decolorization process of oil refining plant.

Tube Filter Press: It is better for crude oil filtering, similar to leaf filter in shape. It has the features of good filtering effect, large filtering area, small land occupation, automatic reside discharging and good environmental health. However, it requires preheating when starting the machine, and the microporous filter tubes need cleaning after using period of time.