Palm Oil Mill Plant Turnkey Projects Provider

A complete palm oil production line is a multi-stage process involving specialized equipment and techniques to convert fresh palm fruit into refined edible palm oil. We provide turnkey palm oil processing plant solutions from oil mill plant layout design to oil machinery manufacturing, onsite debugging, and installation. The palm oil processing plant capacities range from 3tph to 120tph. Our unique patented palm oil equipment and techniques are highly efficient in handling the specific properties of palm fruits and achieving maximum oil yield and quality. We have the best solutions for you in each stage, from palm sterilization and threshing to palm oil extraction and refining. We aim to offer a tailor-made palm oil production plant for every customer and guide you in mastering palm oil extracting and refining technology.

Why Choose Our Palm Oil Machines

- More than 100,000 sqm factory area, over 580 employees, 8 Large-scale workshops, 120 sets of equipment, and over 30 years of experience in oil machine processing.

- We have won 27 national technical patents and can provide specific solutions to meet different requirements.

- We are a large-scale palm oil mill plant project contractor, that can undertake a full set of large-scale palm oil production lines, including palm fruit oil and palm kernel oil production lines.

- Offer you complete palm oil mill equipment, installation, and training service.

- Professional customized palm oil production line design meeting your needs.

- High efficiency, high oil yield, and good energy efficiency.

- Hundreds of successful overseas projects, thousands of large oil mill project experience.

- We can undertake 10,000 t/d oil pretreatment & extraction projects and 1,200 t/d refining projects.

CONTACT US NOW

Take A Glance At Our Palm Oil Mill Plant Projects

50TPD Palm Oil Physical Refining Plant In Peru

15TPD Palm Fruit Oil Mill Plant Project In Congo

30-80 t/d Palm Fruit Oil Production Lines In Indonesia

Palm Fruit Oil Mill Plant Project In Malaysia

Palm Oil Production Line Overview

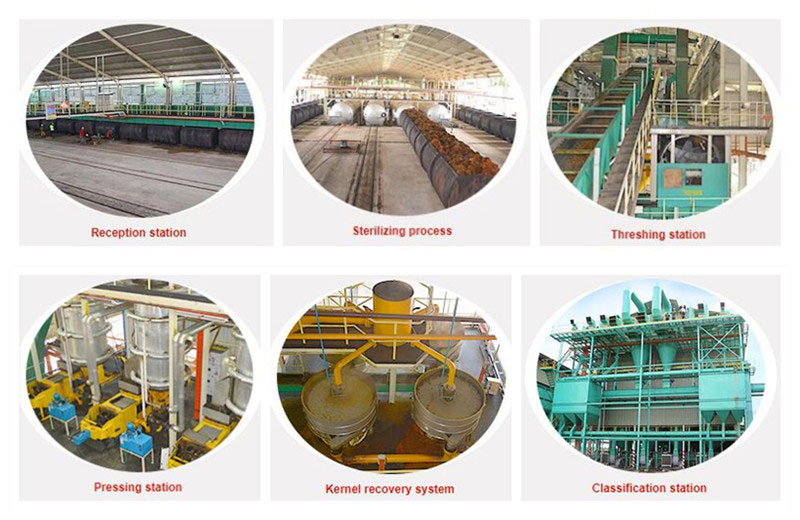

Oil palm is the most economically valuable oil-producing plant in the world, It is widely cultivated in tropical Africa, Latin America, and Southeast Asia. For palm oil plants, our modern palm oil production lines offer scalable, efficient solutions to meet the growing demand for palm oil products in the global market. The Palm Oil Mill process is quite different from other vegetable oil seed processing. Palm fruits contain a lot of fatty acid enzymes, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours. The main stations of the palm oil mill process are the Palm fruit reception station, palm fruit sterilizing station, palm fruit threshing station, palm fruit digesting & pressing station, crude palm oil clarification station, palm nut and fiber separating station, palm kernel recovery station, and palm oil refining plant.

The oil palm Fresh fruit bunches (FFB) are processed in a palm oil mill. The FFB is sterilized, digested, and pressed to extract palm oil. The extracted oil is then clarified and sent to a crude palm oil refinery plant, or palm oil fractionation plant. We have complete patented palm oil production machines, such as palm fruit oil pressing machines, palm fruit crushing machines, palm fruit refining machines, and palm fruit oil fraction machines, to meet your palm processing requirements.

Palm fruit/bunch(FFB) → sterilization → threshing → digesting → clarification → purification →drying → CPO→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

Palm Fruit Treatment Process

Palm Fruit Collection And Reception

Purpose: Transport FFB to the reception station, flow to the scraper conveyer and convey to the sterilizing station.

Process: Palm Bunch Reception is the first step in crude Palm Oil Processing plants. The palm fruit bunch reception process is finished at the loading ramp, which adopts hydraulic segmented discharge. The loading ramp is a platform for palm fruit unloading, cleaning, and storage. Under the slope, there are some cages to receive the palm fruits. To ensure high oil quality, it’s better to process the palm fruits within 24 hours of harvesting.

Palm Fruit Bunch Sterilization

Purpose: FFB transported by scraper conveyer falls into the sterilizing tank, to inactivate enzymes that cause oil deterioration, soften the fruit for easier separation of the fruitless, and get more oil yield.

Process: Rail cars bring raw materials from the reception station into the sterilization tank. FFBs are placed in large sterilizer chambers where steam is introduced to raise the temperature to 130°C to 145°C for 1-2 hours. This also loosens the fruits from the bunch. Palm fruit can easily separate from palm fruit bunches and become soft. Crude palm oil can be easily extracted from palm fruit due to its high humidity. The Palm kernel can also be easily separated from the kernel shell.

Equipment: Horizontal or vertical sterilizer. Steriliser Service Platform. Condensate Pit. Sterilizer Control System. Scraper Conveyors.

Palm Fruit Threshing

Purpose: To detach the sterilized palm fruits from the bunch.

Process: The palm fruit is softened in the sterilizing process and then sent to the threshing machine via the bucket elevator. The palm fruit threshing machine uses strong vibration to separate the palm fruit from the palm bunches. Palm fruit after separation is delivered to the pressing plant. The empty bunches can be used as fertilizer in farmland or palm fruit plantations or pressed into fuel pellets.

Equipment: Palm fruit Thresher drum. Conveyors

Palm Fruit Digestion

Purpose: To crush and soften the palm fruits to release the oil, making the extraction easier.

Process: The palm fruits are sent to a digester where they are heated to 85°C–90°C and mashed through stirring and squeezing, to destroy the palm skin, separate the palm pulp and nuts, and pound the palm pulp, helping to release the oil in the palm oil pressing process. In small palm oil mill plants, the palm fruit digestion process is usually designed without heat insulation and steam injection to reduce cost.

Equipment: Digester with rotating knives and steam heating.

Palm Fruit Oil Pressing

Purpose: To extract crude palm oil (CPO) from the digested fruit.

Process: The digested palm fruits are fed into a palm oil press machine, which applies mechanical pressure to separate the oil from the mesocarp fiber. The commonly used palm oil press machine is a double screw expeller. The pressing process maximizes the extraction of palm oil from the pulp, but the kernels cannot be broken because the crushed palm kernel oil will contaminate the crude palm oil and affect the quality. Using two or more pressing processes can effectively reduce the cracking rate of nuts. The resulting crude oil mixture which contains oil, water, and solids flows out, the crude palm oil will be delivered to the clarification section, and the fiber and nuts are separated and sent for nut recovery. The p

Equipment: Screw oil press machine.

CONTACT US FOR A FREE QUOTE

Crude Palm Oil Clarification

Purpose: To purify the crude palm oil by separating water and impurities.

Equipment: Vibrating screen, settling tank, centrifuge.

Process: The crude oil passes through a vibrating screen to remove large fibers, then goes through a clarifying tank to allow oil, water, and solids to separate. The oil mixture is heated to 85-90℃ and allowed to separate in the clarification tank. A settling time of 1-3 hours is acceptable. Oil from the top is skimmed off and purified in the centrifuge before drying in the vacuum dryer. The final crude palm oil is then cooled and stored. The lower layer from the clarification tank is sent to the centrifugal separator where the remaining oil is recovered. The oil is dried in the vacuum dryer, cooled, and sent to the storage tank. The oil undergoes centrifugation to remove residual impurities, producing clarified crude palm oil. The Plate and frame filters can filter out most of the impurities to make the crude palm oil reach the standard of edible oil. At this stage, the palm oil can be sold as low-quality palm oil or sent on for further processing. For the further palm oil process, the palm oil refining process and palm oil fractionation process are necessary.

Palm Kernel Recovery

Purpose: Separate the palm kernel to extract oil from the nuts.

Process: The nuts are separated during the palm fruit pressing process. The pressed cake(fiber and nut mixture) is transported to the fiber separation system for fiber and nut separation by the physical method. The nuts are sent to the nut silo. The palm kernel will be recycled from the nuts by the cracking machine. The palm kernels are further processed in the palm kernel oil extraction plant to produce palm kernel oil (PKO) and palm kernel cake (PKC).

Equipment: Nut and fiber separator, nuts cracker, Palm kernel oil press.

Crude Palm Oil Refinery(CPO)

Palm Oil Refinery is an important process in the palm oil mill plant to ensure the quality and safety of palm oil. It’s recommended to refine crude palm oil through our palm oil refining machines to get high-quality palm oil that is easy to store and can priced high. Refined palm oil can be packed and labeled for the local or global market. We offer you complete palm oil pressing refining plant solutions, from plant layout design to palm oil equipment manufacturing, debugging, and installation.

We offer various palm oil refining plants to meet customers’ special capacity needs, including Batch Refinery plants, Semi-continuous Refinery plants, and Continuous Refinery Plants. The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

Large Palm Oil Refining Plant

Capacity: 50-1500T/D

Small Palm Oil Refining Plant

Capacity: 1-5T/D

Crude Palm Oil Refining Plant Working Stages

The main steps of crude palm oil refining are degumming, deacidification, bleaching, and deodorization.

CPO(crude palm oil)→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

Palm Oil Degumming Equipment

Palm Oil Deacidification Equipment

Palm Oil Bleaching Equipment

Palm Oil Deodorization Equipment

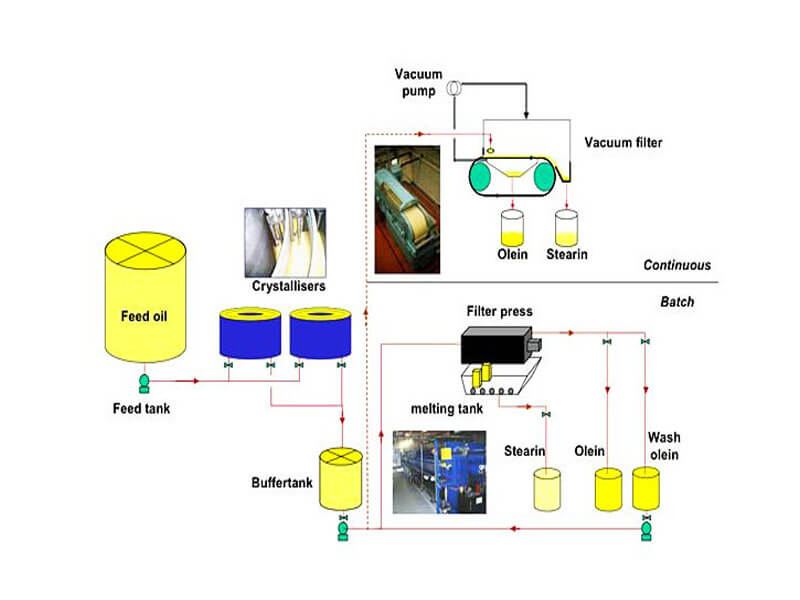

Palm Oil Fractionation Plant

Capacity: 1-500TPD

Fractionation is the special treatment for palm oil. According to customers’ requirements, we can customize the Fractionation process to Separate solid and liquid parts of the oil, allowing the production of palm olein (liquid) and palm stearin (solid). A palm oil fractionation plant is a good choice if you want to increase the added value of palm oil products and the economic benefit of your enterprise. Our palm oil fractionation plant adopts advanced crystallization equipment, filtration equipment, and accurate temperature auto-control software to separate palm olein and palm stearin which can get different melting-point fractionation products, including 18℃, 24℃, 32℃, etc.

Lowering the palm oil temperature to about 24 ℃ for a definite time will crystallize and separate the ingredients with a high melting point. After secondary filtration, the palm oil can be fractionated into three products with different melting points, which are palm stearin (melting point>40℃), palm palmitin (melting point about 30℃), and liquid palm oil (melting point <20℃). The quality of liquid palm oil can reach the standard of high-level edible oil.

Palm Oil Fractionation Plants

Palm Oil Fractionation Plant Flowchart

Palm Oil Fractionation Technical Process

The fractionation methods of palm oil are composed of dry fractionation, solvent fractionation, and surfactant fractionation.