Edible Oil Production Line Overview

A Small edible oil production line is designed for small to medium-scale edible oil mill plants, with capacities ranging from 1 TPD to 50 TPD, providing an efficient, cost-effective solution for producing high-quality edible oils from various oilseeds. This production line is versatile and suitable for processing oilseeds like sunflower, soybean, peanut, canola, rapeseed, sesame, and more. This is an affordable and customizable edible oil production solution that lets you meet local or small-market demands and provides a profitable way to turn oilseeds into marketable oil products.

Features of the 1 – 50 TPD Edible Oil Production Line

Flexible Capacity: Suitable for small-scale (1-5 TPD) to medium-scale (10-50 TPD) edible oil production needs.

Customizable Equipment Options: Adaptable to specific requirements, including cold or hot pressing and optional solvent extraction.

Compact and Efficient Design: Minimizes space requirements and maximizes efficiency.

Ease of Operation: User-friendly, requires minimal labor, and is easy to install and operate.

Cost-Effectiveness: Lower initial investment, energy-efficient, and cost-effective, making it suitable for small businesses.

Adaptable to Different Oilseeds: Versatile design allows for processing various oilseeds.

High-Quality Output: Provides filtered or refined oil that meets quality standards, suitable for direct sale or further refining.

CONTACT US TO GET A FREE QUOTE

Edible Oil Production Line Working Process

The complete edible oil production line including oilseed shelling, cleaning, crushing, cooking, pressing, and refining. The equipment may be get a tiny adjustment according to the different oilseed materials.

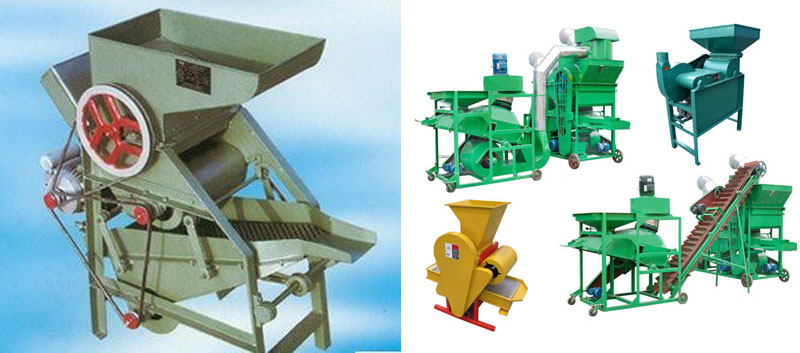

1. Oilseed Dehulling Cleaning and Crushing

Purpose: Break down the seeds to facilitate easier oil extraction and reduce fiber content.

Equipment: Crushers and dehullers.

Process: Oilseeds like sunflower, almonds, and peanuts go through dehulling to remove outer shells while crushing breaks the seeds to increase the surface area for better extraction efficiency.

To get palm kernel seeds, a palm kernel crusher is necessary to offer integral palm kernel seeds.

For copra or coconut oil, a copra cutter is needed to cut large copra pieces into smaller ones for copra oil extraction.

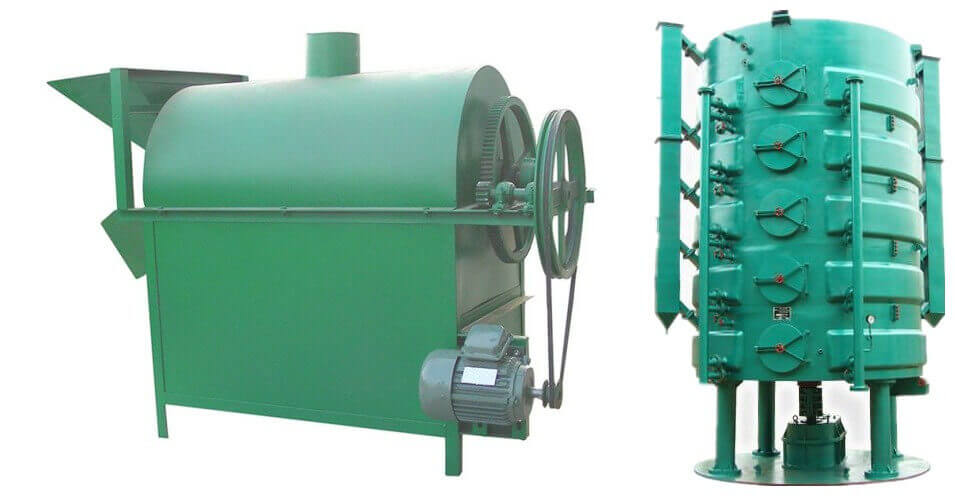

2. Oilseed Roasting Cooking Machines

Purpose: Prepare the oilseeds by adjusting moisture and temperature, making them suitable for oil pressing, increasing oil yield, and improving oil quality during pressing.

Equipment: Two types of oil seed roasting cooking machines are mostly used: rotary roasting machines and vertical steam roasting machines.

Cooking can break oil seed inner cells, make the protein nature change, and reduce oil fat stickiness for easy pressing. Oilseed roasting is especially suitable for peanut, sesame, and cottonseed oil pressing due to these seeds’ special characteristics. The roasting machine has strong adaptability to energy sources and is low-cost. Steam roaster has a large capacity and is good for large oil processing plants.

3. Mechanical Oil Pressing (Cold or Hot Pressing)

Purpose: Extract oil from oilseeds through mechanical pressure.

Equipment: Screw oil press machines.

Process: Depending on the oilseed type and desired oil quality, cold pressing (without heat) or hot pressing (with heat) is used to expel oil. The pressing process can typically yield up to 70-80% of the oil content in the seeds.

Pressing is a key part of edible oil production. We offer various types of oil press machines for different oil extraction scales. Integrated oil press is an advanced design that combines oil pressing and filtering. The screw oil press is widely applicable in over 20 kinds of oilseeds. Hydraulic oil presses are hot in the countryside or in small oil mills for extracting small-capacity oil.

4. Oil Filtration

Purpose: Separates impurities, such as seed particles, to clarify the oil.

Equipment: Plate filters, leaf filters, or frame filters.

Process: The oil passes through the filter to remove solid residues, resulting in a clearer, more marketable product.

5. Crude Oil Refining Plant

Refining is essential to improve the oil’s taste, smell, color, and stability, ensuring it meets market standards. Oil refining plants can be tailored for first and second-grade oil production. The total refinery plant contains refining pot, decolorizing pot, deodorizing pot, steam generator, heat conduction furnace, etc.

Degumming and Neutralization: Removes phospholipids and free fatty acids to improve flavor and stability.

Equipment: Degumming tank, neutralizing tank.

Process: Crude oil is treated with water or an acid solution to remove gums, then neutralized with alkali to reduce acidity.

Decolorization (Bleaching): Reduces pigments like chlorophyll, enhancing the oil’s color.

Equipment: Bleaching tanks, filter press.

Process: Oil is mixed with bleaching earth or activated carbon and filtered to achieve a lighter color.

Deodorization: Removes volatile compounds that cause odors.

Equipment: Deodorization tank, vacuum pump.

Process: Oil is heated under a vacuum, allowing steam to strip out odor-causing molecules.