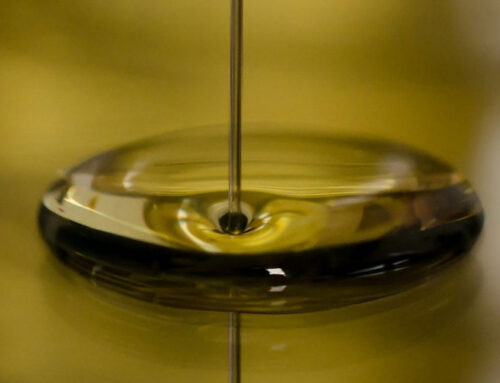

Edible Oil Cold Pressing VS Hot Pressing

There are two types of oil press, cold pressing, and hot pressing. Just as the name implies, the cold pressing means pressing under low temperature, the oilseeds can be pressed without roasting. While hot pressing is pressing under high temperature, the oilseeds are pressed after roasting. There is special oilseed roasting machine for use.

The Difference in View of Process

Most oilseeds are not suitable for cold pressing. The material of edible oil cold pressing must be selected, otherwise, the different maturity and hazardous substance will seriously impact the quality of the oil. The fragrance of sesame oil and superfine fragrant peanut oil must be got from hot pressing. The edible oil after cold pressing generally needs no refining. However, part of phospholipid contents and acid value may be on the high side, and the nuts residue is hard to avoid. To protect the healthiness and beautiful color of oil, refining shall be adopted. Refining means removing the impurity, reducing the niger oil content and stabilizing the fatty acid value by using a metering pump, oil filter, vacuum pump and so on. The crude oil of hotly pressed oilseeds is deep in color and high in acid value. It must be refined before eating.

For cold pressing, the oilseeds must be crushed first so that we get a considerable output. Sometimes second and even third pressing is required. Hot pressing is usually used for large equipment pre-press, i.e. first pressing. However, some manufacturers have improved machines that can directly press oil without using other equipment.

The Difference in View of Nutrition

Cold pressing is safer and nutrient. Cold pressed oil is all natural. It retains the natural relish and color of oilseeds, and wholly preserves the physiological activator in oil. It is a good choice for healthy living. As one kind of oilseeds productive technology, cold pressing is out in the cold compared with hot pressing, the reason is that the oil yield of cold pressing is only half of the hot pressing, however, cold pressing can completely preserve the nutrient in oilseeds, since the whole process is under 60°low temperature, and no chemical agent is needed. Because of the difference in oil yield, the price of most cold pressed oil is 50% higher than hot pressed oil.

Due to the limitation of equipment, traditional technology usually adopts the hot pressing method. But as human temperature sensing is not able to be accurate, the temperature often gets too high, while benzene and other hazardous substance are easily produced. The physiological activator in oilseeds also has a heavy loss.

The Difference in View of Market

Cold pressed oil is nice and shallow in color. There is no foam when frying. But it’s not so fragrant, and may have unripe flavor, tasting not so good. Hot pressed oil has a pure flavor. It’s fragrant, especially sesame and peanut which have rich oil. The disadvantage is that there will be foam when frying if without processing. But just simple treatment can solve this problem.

As consumers, if you like fragrant flavor, you can purchase hot pressed oil. The edible vegetable oil in our life is often hot pressed oil. With the improvement of living standard in recent years, people have a larger demand for healthiness and quality. Cold pressed oil is becoming more and more favored. It doesn’t destroy the cell of the grease and linoleic acid tissue and is more green and healthy. For cold pressing, we usually use hydraulic oil press, while generally, we use screw oil press for hot pressing.