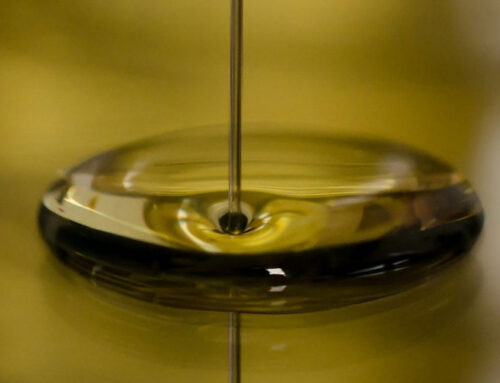

Why Should Free Fatty Acids Be Removed from Edible Oil?

When the oil has a high content of free fatty acids, the irritating smell will be produced, influencing oil flavor, and expediting the hydrolytic rancidity of the neutral oil, so we must try to remove free fatty acids. The removal can be through a chemical process and physical process.

How to Remove Free Fatty Acids by Neutralization?

Alkali Refining

Using caustic soda in neutralization has the following advantages:

1. low price and wide sources.

2. Strong alkalinity.

3. The soap-stock is well separated with oil.

4. Most FFA can be separated effectively.

5. High decolorizing ability

Physic-chemical process

There are also physic-chemical processes besides neutralization during alkali refining.

* Reacting most of the free fatty acid with caustic soda to form sodium soaps referred to as soap-stock. The soap-stock is oil insoluble flocculating jell, and can be separated out.

* Soapstock has strong absorption ability. Quite a lot of impurities like residual proteins, pigments, phosphatides, trace metals and oxidizing materials are absorbed and removed.

* In the case of crude cottonseed oil, free gosspyl can react with the alkaline solution and forms phenoxide, which is easy to be absorbed onto soapstock and removed, so that the color of cottonseed oil is lowered.

During alkali refining, part of neutral oil reacts with caustic soda, i.e. is saponified, and goes into the soapstock, resulting in increased refining loss. Meanwhile, some neutral oil is also entrapped in soapstock and carried away. To reduce the loss of neutral oil and increasing refining rate, we shall choose the best-operating conditions. For oil which has high acid value, re-refining with caustic soda is required.

Batch type neutralization pot

Neutralization can be carried out either by the batch process with neutralization pot neutralization pot or by a continuous process with centrifuge. For small oil processing plant, the batch type is usually adopted. Degumming is required before neutralization of the crude oils often have a high phosphatide content, which negatively affects the yield. Improper neutralization will result in problems in subsequent refining steps of bleaching and deodorizing.

By-product of Neutralization of Free Fat Acid

The by-product soapstock is processed for the product acid oil containing free fatty acid and glyceride, which is mostly sold as livestock feed. Acid oil is also used as a feedstock for soaps, biodiesel, and fatty acid industrial production.