What Should Be Paid Attention to Increase Oil Yield

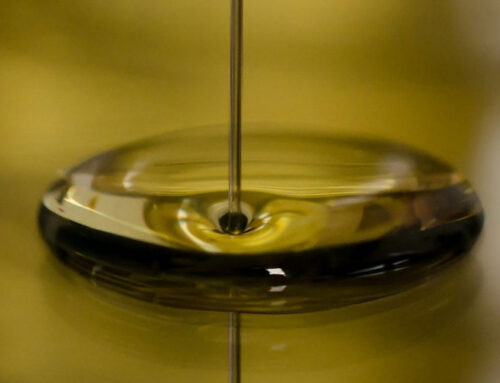

Oil yield is an important factor in oil production. It is closely related to the materials’ oil content, technology and operation method.

1. Oilseeds

The quality of oilseeds such as satiation degree, impurity content, variety and moisture content is important. Different oilseeds have different oil content. Proper pretreatment process could improve the properties of feeding material, achieving the best pressing effect, increasing oil yield. A complete pretreatment process includes drying, cleaning, hulling, flaking, puffing, crushing, and cooking.

2. Squeezing Process

(1) The Pressure in Pressing Chamber

The essence of oil pressing is that taking oil out by exerting pressure on oilseeds. In the process of pressing, uneven pressure distribution and oil flow velocity will cause the uneven distribution of residue oil. The lower the residue oil rate, the higher the oil yield. The main factors that influence pressure in pressing chamber are cake thickness, feed quantity and pretreatment quality (the oilseeds moisture content and temperature, etc.).

If the oil cake is thin, the resistance to motion of oilseeds will increase, so the pressing chamber pressure will be higher, and oil yield will be high. But if too thin, the enlarged machine burden may cause an accident.

At the beginning of pressing, feeding should be even and slow. Too fast feeding causes the sudden increase of pressing chamber pressure and further the breakdown of oil press.

The feeding material should have proper moisture content and temperature. It should have good fluidity. The viscosity and surface tension of oil should be as low as possible, ensuring the feeding material has appropriate plasticity and elasticity, keeping the normal pressure in pressing chamber. High moisture makes the material form blocks. When the moisture content is low, the material will be pressed to powder, coking easily and blocking the pressing chamber. If the temperature is too high, the oil quality will be affected. Too low temperature couldn’t form normal conditions for physical and chemical changes. The practice has proved that the oil yield efficiency of hot pressing is higher than cold pressing.

(2) Pressing Period

Usually, the longer the pressing period, the higher oil yield. However, too long time can cause unnecessary heat loss, which is against the improving of oil efficiency and influences the handling capacity of the equipment. On the premise of meeting oil efficiency, we should make the pressing period as short as possible. There are three factors that decide the material’s dwell time in the pressing chamber, screw shaft’s revolving speed, the aging degree of pressing crew and pressure ring, along with the thickness of the cake. For those oilseeds that have high oil content, we could choose proper rotating speed, adequately extend pressing time.

(3) The Temperature of Pressing Chamber

The temperature change of the pressing chamber will directly influence the plasticity of oilseeds and oil viscosity, further influencing pressing effect and oil yield efficiency. The too high temperature will result in the deepening of the color of cake and oil, as well as the increase of residual oil ratio. If the temperature is insufficient, the oilseeds will not have normal pressure in pressing chamber and will not form oil cake.

3. Operation

The new machine may be damaged during storage, load & unload and transportation. Improper installation, operation, and maintenance will influence the quality of oil products and production capacity. Necessary production, pretreatment, and reprocessing equipment should be well prepared to increase productive efficiency.