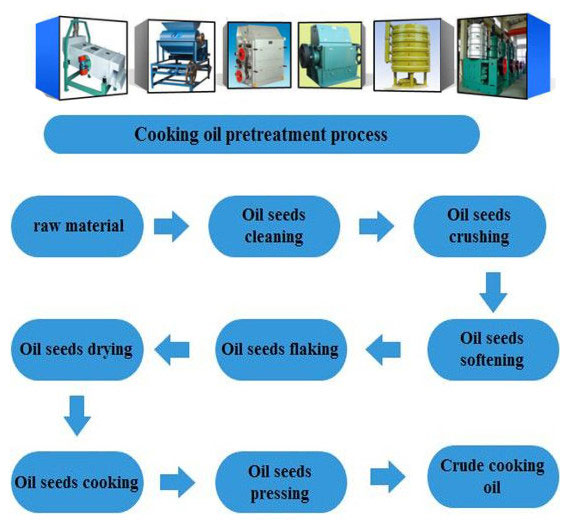

Oilseeds Pretreatment

Objective: To improve the appearance of the oilseeds for the convenience of making oil.

Procedures of Oilseeds Pretreatment

1. Cleaning

Inevitably, there will be impurities in the oilseeds that entering the oil plant. If the soil, stem, and leaves are not removed before pressing, the quality of oil and seed cake will be affected, some oil will be absorbed by these impurities so that oil yield will decline. Sand not only affects the normal work of oil press but also largely shortens the service life of pressing screw, pressing bar and cake outlet. Stone, metal and other hard materials in the oilseeds will damage the pressing screw at once.

There are many ways to remove the impurities. For light materials such as grass, stem, and leaves, air classification can be adopted. If the impurities are small, we could remove them by screening separation. For those materials whose size and relative density are similar with oilseeds, clod can be smashed in the sand machine first and then screened. Irony impurities can be separated by an electromagnet or permanent magnet.

2. Hulling

For oilseeds with husk, we should remove the shell before pressing, so the throughput and oil yield can be improved.

3. Crushing

The aim of crushing is to reduce the size of the seeds, ensuring the uniformity of cooking. Too big or too small sizes are all to the disadvantage of oil outlet. Too big oilseed will obstruct the oil path. Too small oilseed will be brought way when pressing, increasing the resistance to oil flowing, and even blocking the oil path. Meanwhile, small oilseeds will make the plasticity of pressing material larger, which goes against the pressure’s increasing, causing unnecessary reclaim. Large plasticity will also make the oil come out in advance in the form of solid cake or oil of bad quality. Some oilseeds can be pressed in its whole form, but after crushing and flaking, oil yield is obviously improved.

4. Flaking

Destroy the cellular structure of the oilseeds, making oil extracting easier. The more cells are destroyed, the better.

5. Drying

The oilseeds should be dried before pressing. Proper water content will result in high oil yield, high output, and high-quality oil.

6. Cooking

This process is not only important for the oil yield but also closely linked with the service life of oil press. The pressing material should contain proper amount of water and have good fluidity. It should have a necessary temperature, lowering the viscosity and surface tension of oil in it, ensuring the good fluidity of oil when pressing. The method that often adopted is wetting the oilseeds first, and then drying them by roasting machine, adjusting the water content to an ideal state. One of the matched equipment is oilseeds roasting machine. It is indispensable as well as crucial in the oil press production line. Different oilseeds have different characteristics, they shall be cooked to a certain extent accordingly.

7. Puffing

Sometimes this process will be adopted to optimize the leaching property of oilseeds.