For the people who are engaged in oil processing industry or interested to join, how to increase the oil quality has become increasingly important, especially the pressed oil. There are two main factors affecting the pressed oil quality, namely oilseeds structure property and pressing conditions.

1. Oilseeds Structure Property

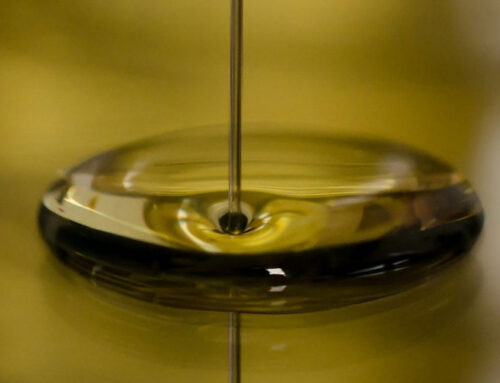

The structural properties of oilseeds mainly depend on the pretreatment and composition of oilseeds themselves. The oilseeds should be in appropriate and consistent size. And the less amount of complete cells in oilseeds, the better. The density of oilseeds is as higher as possible on condition that the interior and exterior structure is not affected. Besides, lower the oil viscosity and surface tension as much as possible, ensuring good fluidity of oil in the pressing process. Additionally, the oilseeds need to have enough plasticity.

Factors Influencing Oilseeds Structure Property

* Moisture content

Plasticity of oilseeds increases gradually with the increased moisture content. When the moisture content reaches to a certain degree, the oil press reaches its optimal performance.

* Temperature

Heat the oilseeds, the plasticity will be increased. Lower the temperature greatly, the oilseed cake will be unshaped. However, the temperature should not be too high, otherwise, some substances will be decomposed into gas, or burnt smell will be produced.

* Protein Denaturation

It is a necessary process for pressing the oil. Whether the protein is fully denatured measures the destruction degree of colloidal structure in the oilseeds. When pressing, the protein will be denatured under the impact of high temperature and pressure. However, if the temperature and pressure are inappropriate, the excessive protein denaturation is not conducive to press the oil, while inadequate denaturation can affect the oil refining.

2. Pressing Conditions

* Pressure in Pressing Chamber

We get the oil through putting the pressure on the oilseeds. The thickness of oilseed cake, amount of feed and quality of pretreatment affect the pressure in the pressing chamber. The thinner oilseed cake and higher pressure lead to high oil yield. While the ultra-thin oilseed cake may increase the load of the machine, resulting in an accident. Therefore, the uniform feeding is quite necessary.

* Pressing Time

Pressing time is an important factor influencing the production capacity and oil yield. Generally, the longer pressing time, the higher oil yield. However, too long pressing time may lead to unnecessary heat loss, affecting the oil yield. Minimize the pressing time as short as possible provided that the oil yield can satisfy the requirement.

* Temperature in the Pressing Chamber

The temperature in the pressing chamber directly affects the plasticity of oilseeds and viscosity of the oil, further affecting the oil yield and quality. However, the too high temperature will deepen the color of oilseed cake and increase the residual oil rate. And the oil cannot be pressed so much with low temperature. Therefore, an appropriate temperature cannot be neglected.