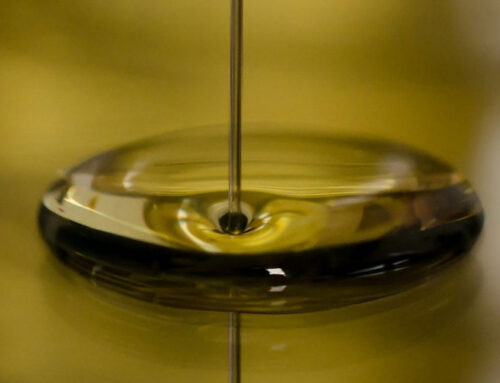

Edible Oil Refining

Edible oil is extracted from coconuts, corn germs, cottonseeds, olives, palm fruits, palm kernels, peanuts, soybeans and sunflower seeds etc. In many markets further refining is not required as the flavors of unrefined oils may be readily acceptable. However, oil refining process is carried out in large-scale operations and for international markets which tend to prefer a less-colored and odorless product.

|

|

|

It is very necessary that the oil refining process be known to the oil mill plants owners. The crude oil obtained from oil mill plants and solvent plants get refined in the oil refinery plants before it is utilized directly. The oil through the oil refining process gives color uniformity and appealing quality to the oil by removing unpleasant smell and undesirable factors from the oil.

The Refining Steps Are● NeutralizationFatty acids can be neutralized by adding a sodium hydroxide solution, also known as caustic soda, or by stripping, which is a similar process to de-odorizing. ● BleachingSome oils have a very dark color which can be unpopular with consumers. The appearance of the oil can be lightened by bleaching. ● DeodorizingVolatile compounds that produce odors can be eliminated through the process of sparging, i.e. bubbling steam through the oil, under a vacuum. ● DegummingDegumming is a way of treating oils that have high phosphate content. The phosphate, which makes a gummy residue, is removed by mixing the oil with 2% or 3% water. This hydrated phosphate can then be removed by settling, filtering or centrifugation. ● WinterizationAllowing the oil to stand for a time at low temperatures so that glycerides, which naturally occur in the oil, with higher melting points solidify and can then be removed from the oil by filtering. This step is usually carried out with palm oil to separate the oil into two separate products: solid fat (stearin) and liquid oil (olein). |