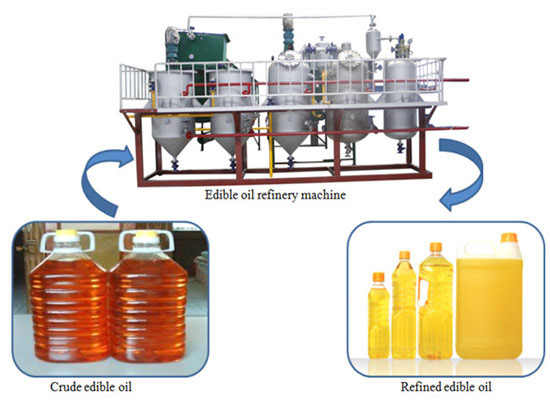

Batch Type Small Edible Oil Refining Plant Overview

Batch-type edible oil refining equipment offers a practical solution for small-scale edible oil production, combining flexibility, efficiency, and high-quality output. Its modular design, ease of operation, and cost-effectiveness make it an excellent choice for the small-scale oil mill plant, ideal for producing high-quality refined edible oil with flexibility in processing different types of crude oils.

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

Features of Batch Type Edible Oil Refining Equipment

- Compact Setup: The equipment is designed to be modular, making it easy to install, operate, and maintain.

- Flexible Configuration: Allows for easy modification to handle various types of crude oils and refining processes.

- Batch Processing: Operates in batches, ideal for small-scale edible oil production or experimenting with different oils.

- Customizable Settings: Adjustable parameters for different refining steps, such as degumming, deacidification, decolorization, and deodorization.

- Precise Control: Ensures consistent quality and high purity of the refined oil. Allows for adjustments during the refining process.

- Ease of Operation: User-Friendly. Simple controls, easy operation, and maintenance

Equipment of Batch Type Edible Oil Refining Line

A refining pot, decolorizing pot, deodorizing pot, vacuum pump, steam generator, and heat conduction furnace are necessary for the edible oil refining process. They are connected with vessels by pipeline.

Advantages of Batch Type Edible Oil Refining Equipment

- Affordable Setup: Lower initial investment compared to continuous refining plants.

- Low Operating Costs: Reduced energy consumption and chemical usage, leading to lower operational costs.

- High Flexibility: Capable of refining various types of oils, including palm oil, soybean oil, sunflower oil, and more. Best choice for small-scale edible oil mill plants or those looking to experiment with different oil types and refining conditions.

- Ease Operation and Maintenance: Designed for easy maintenance with accessible components and minimal downtime.

- Real-Time Monitoring: Allows continuous monitoring and adjustment, enhancing process efficiency and product quality.

Batch Type Edible Oil Refining Equipment Applications

- Small-Scale Edible Oil Production: Ideal for local markets, small oil mill plants, and home-based edible oil producers. Provides flexibility for processing various types of crude oils.

- Pilot Plants and R&D: Suitable for research, development, and testing of new refining processes and oil types.

- Custom and Niche Markets: Perfect for edible oil producers catering to niche markets with specific quality requirements or specialty oils.