Do You Have An Edible Oil Mill Project We Can Help With?

Specialists In Edible Oil Mill Plant

Offer You A Complete Edible Oil Production Plant Solution

Professional Edible Oil Plant Supplier. Over 30 years of experience in edible oil machines. We are committed to offering one-stop turn-key edible oil plant solutions. Choose our edible oil machines, you work with a team that understands your edible oil production business.

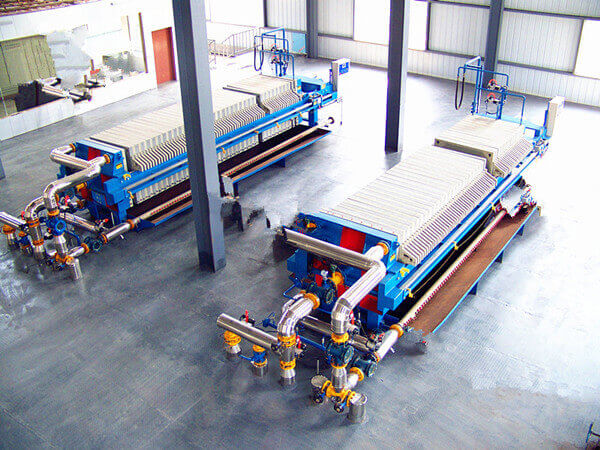

Our Factory Show

To be your Premier Edible Oil Plant Supplier.

WHY US

- China leading oil machine supplier. 100,000 ㎡Modern workshop.

- Customer satisfied. We Built Over 100 edible oil production factories worldwide.

- Over 30 years of experience in edible oil machines. Offer you a complete edible oil production solution.

- Best support. Over 20 overseas offices. We have spare parts warehouses or offices in every continent.

- Over 100 patents and publications of edible oil machines, dozens of international and national honors.

- Strong research capabilities, professional R&D laboratory.

GET A QUOTE NOW

Explore Oil Mill Plants

We have built over 100 edible oil production lines worldwide, covering almost all oilseeds raw materials. And we have spare parts warehouses or offices in every continent. The technical teams are ready to help you design and install oil mill plants based on your oilseed type, yield & budget. Technical support from oil machine selection, and capacity optimization to training and operation. We are your oil mill project designer and investment counselor.

Our Vision

Be the most trustworthy supplier of healthy edible oil equipment.

Over 20 overseas offices and spare parts warehouses. We are always ready to support your edible oil production business.

Edible Oil Mill Plant Solutions

Take a look at some of our edible oil production solutions and tell us what can we do for you.

We offer deep customization design in edible oil mill plants and refining projects. From market analysis to plant layout, the oil mill plant design to precision manufacturing. We are committed to offering you a one-stop turnkey solution.

Edible Oil Production Steps

The edible oil production line usually includes the oilseeds pre-treatment, oil pressing process, and edible oil refinery process.

Pretreatment

The Oilseeds pretreatment section is the most important part of the edible oil processing plant. Different oilseeds need different preprocessing machines.

Prepressing

The oilseed pre-pressing section is mostly for pressing high oil-content material and also for pre-pressing low oil-content seeds before solvent extraction.

Extraction

Solvent extraction section is to extract edible oil from oil cakes or flakes by solvent. This extraction method can produce quality oil with large capacity & low cost.

Refinery

The crude oil refinery section is essential to remove impurities from crude edible oil. You can choose batch type, semi-continuous, or full continuous refinery machinery.1 Oilseeds Preprocessing Section

Different pre-treatment ways are adopted for different oilseed materials in oil mill plants. you can refer to our edible oil production lines for more detail, however, it usually includes oilseed cleaning, de-stoning, cracking, cooking, and faking. After that, the oilseed is made into a cake shape. The oilseed cakes are sent to the oil press machines for pressing crude oil.

2 Oil Pressing Step

It is to extract the oil from the oil material by pressing. four types of oil pressing are usually used. 1, Single pressing is usually applied at small-capacity oil milling plants. 2, Pre-pressing is for larger capacities oil mill plants. 3, Hot Pressing is to cook the oil seeds before pressing to get a high oil press yield. 4, Cold Pressing is to press oil seeds using only the application of pressure, without heat or chemicals.

3 Solvent Extraction Step

Solvent extraction is a process of extracting oil from oil-bearing materials using a solvent. A typical solvent used is hexane. The solvent extraction plant is designed to extract oil from oil seeds containing less than 20% or from pre-pressed or fully pressed oilseed cake containing more than 20%. We have a wide range of Solvent Extraction equipment with capacities from 300 kg to 100 metric tons.

Edible Cooking Oil Extraction Projects We Offer

- 30-5,000T/D Soybean oil solvent extraction plant

- 30-5,000T/D Rapeseed oil solvent extraction plant

- 30-5,000T/D Peanut oil solvent extraction plant

- 30-5,000T/D Cottonseed oil solvent extraction plant

- 30-5,000T/D Sunflower oil seed solvent extraction plant

- 30-5,000T/D Corn germ oil solvent extraction plant

- 30-5,000T/D Castor oil solvent extraction plant

- 30-1,000 T/D Rice Bran oil solvent extraction plant

- 30- 1,000 T/D Flaxseed oil solvent extraction plant

- 30-500 T/D Tea seed oil solvent extraction plant

- 30-500 T/D Sesame oil solvent extraction plant

- 30-500 T/D Walnut oil solvent extraction plant

- 30-500 T/D Safflower seed oil solvent extraction plant

- 30-500 T/D Cyperus oil solvent extraction plant

4 Edible Oil Refining Step

Edible oil refining includes a series of processing procedures such as degumming, neutralization, bleaching, deodorization, and winterization. No matter the physical or chemical refining equipment, we have suitable edible oil refining machines to refine almost all kinds of edible oil such as sunflower oil, peanut oil, sesame oil, soybean oil, etc.

What Oil Refinery Projects We Offer

- 30TPD – 1,200TPD Soybean oil refining plant

- 30TPD – 1,200TPD Rapeseed oil refining plant

- 30TPD – 1,200TPD Peanut oil refining plant

- 30TPD – 1,200TPD Cottonseed oil refining plant

- 30TPD – 1,200TPD Sunflower oil refining plant

- 30TPD – 1,200TPD Corn germ oil refining plant

- 30TPD – 1,200TPD Castor seed oil refining plant

- 30TPD – 1,200TPD Palm oil refining plant

- 30TPD – 500TPD Rice bran oil refining plant

- 30TPD – 500TPD Flaxseed oil refining plant

- 30TPD – 300TPD Tea seed oil refining plant

- 30TPD – 300TPD Sesame oil refining plant

- 30TPD – 300TPD Walnut oil refining plant

- 30TPD – 300TPD Safflower seed oil refining plant

CONTACT US FOR A FREE QUOTE

Let’s Start Your Edible Oil Project

Edible Oil Milling & Refining Projects Cooperation Process

1 MESSAGE

2 QUOTATION

3 DISCUSSION

4 PROJECT DESIGNS

5 CONTRACT

6 MANUFACTRUIING

7 DELIVERY

8 INSTALLATION DEBUGGING

9 AFTER SERVICE

FAQs For Edible Oil Production Lines

FAQs for Technology, Machines, Customization, Project Design, Installation, Training, and After-Sales Service